Transparent Hydraulic Transmission and PLC Control Training Device

The transparent hydraulic transmission and PLC control training device is developed by our company in accordance with the teaching syllabus requirements of colleges and universities for electromechanical integration in pneumatic, electrical, and hydraulic control. Drawing on the advantages of our company’s hydraulic PLC control training equipment, it adopts an open comprehensive training platform structure. It has been continuously innovated and improved after extensively soliciting opinions from experts, professors, and teachers. It is currently an ideal comprehensive training equipment for hydraulic transmission control technology combined with PLC control. Through training, students can intuitively and perceptually compare and understand the characteristics, features, advantages, and disadvantages of electrical, hydraulic, and manual control methods.

I. Main Technical Parameters

- Power supply: AC220V with a tolerance of ±10%, 50Hz;

- DC power supply: input AC220V, output DC24V/3A;

- Device capacity: ≤1kVA;

- Operating environment temperature: -5℃~40℃;

- Operating humidity: ≤90% (at 40℃);

- Overall dimensions: 1500mm×700mm×1750mm;

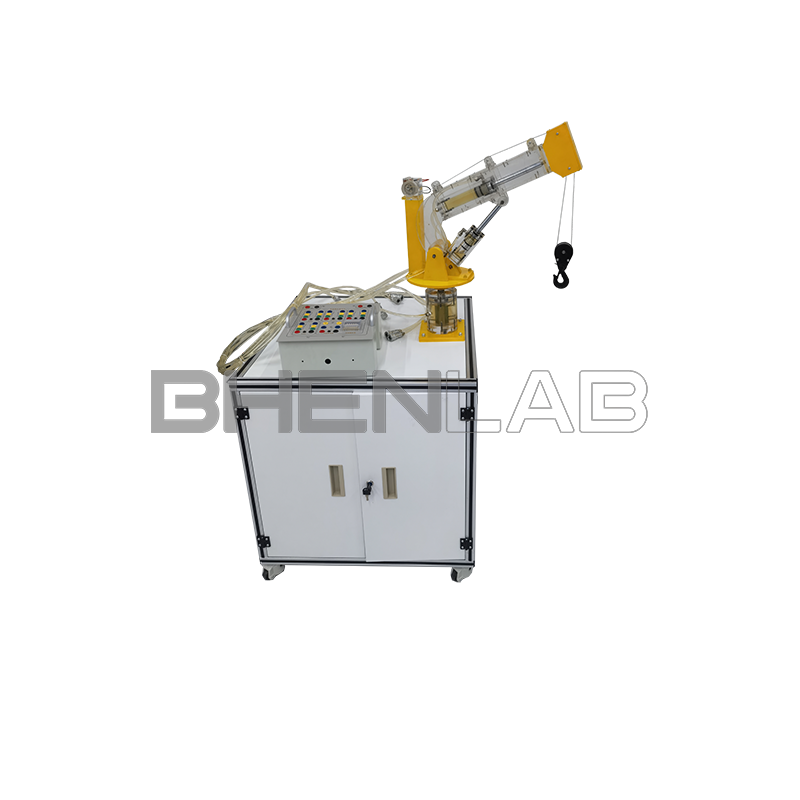

- Hydraulic pump station:

(1) Rated system pressure: 0.8MPa;

(2) One set of fixed displacement gear pump and motor: 采用内轴一体式安装,结构紧凑,噪音低;定量齿轮泵:额定流量 6L∕min,压力 2.5 MPa;电机:功率 250W,调速范围 0-1500r/min,外型尺寸:630mm×380mm×500mm。

Oil tank: with a capacity of 45L; equipped with an oil temperature and level gauge, filter, air filter, shock-resistant pressure gauge, and filled with L-HL46 hydraulic oil; - Hydraulic components:

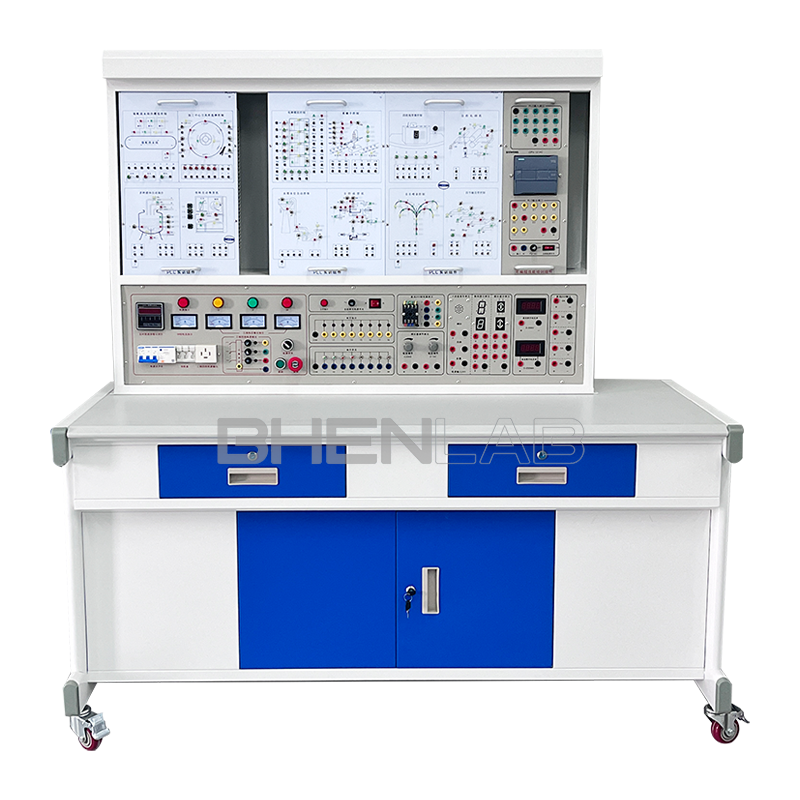

Processed with transparent technology, with a maximum working pressure of 2.0MPa. Each transparent hydraulic component is equipped with a base plate, which can be conveniently and freely placed on the operation panel. The oil circuit connection adopts quick-change connectors and transparent hoses, allowing clear and intuitive observation of oil flow without oil leakage. - Electrical control unit:

(1) Power module: The power part is equipped with a 380V voltmeter, DC voltmeter, and ammeter to monitor the input AC/DC power supply and current indication of the device. The start/stop buttons are mainly used to control whether the hydraulic pump station and air pump are energized. An emergency stop button is configured to provide AC220V AC voltage and DC24V DC voltage in the electrical control circuit.

(2) PLC host module: The host uses Mitsubishi FX1S-20MR, with 12 channels of DC input and 8 channels of relay output.

(3) Equipped with control modules: PLC input and output modules; relay modules; control button modules; time relay modules, etc. - Solenoid directional valve: DC24V, suction 3MPa

II. Main Features

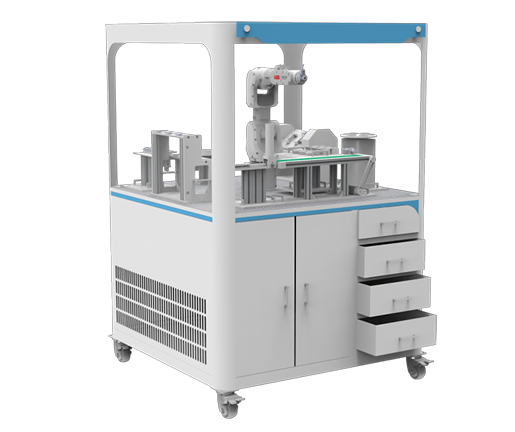

- The hydraulic PLC control training device is mainly composed of a training desk, training platform, hydraulic components, electrical control devices, programmable logic controller (PLC), and other components.

- The training desk and platform adopt a double-layer iron structure with matte dense-grain spray coating. Hydraulic components, etc., are stored in the drawers of the training desk.

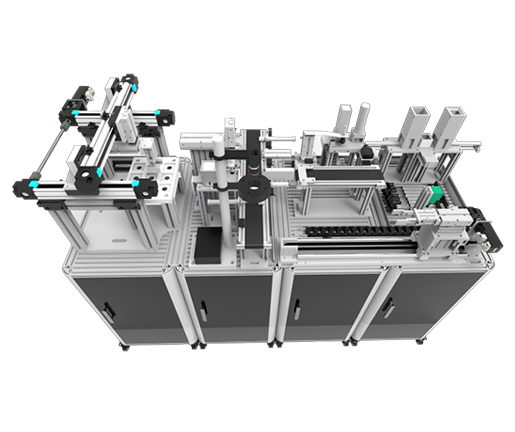

- Equipped with all common hydraulic components: Each hydraulic component is equipped with a mounting base plate, which can be conveniently and freely installed on the aluminum profile panel (the panel is an aluminum profile structure with a “T” groove). The oil circuit connection uses quick-change connectors, making disassembly and connection convenient without oil leakage.

- Training components are made of transparent organic materials, facilitating understanding and mastery of the structure, performance, and uses of dozens of common hydraulic components. It enables mastery of the working principles of dozens of basic circuits, with quick and convenient experimental circuit assembly.

- Integrating mechanical control, traditional relay control, advanced PLC automatic control, PLC programming, and monitoring technology, it flexibly realizes its functions.

- The experimental control unit can also use an independent relay control unit for electrical control. Through comparison, the superiority and advancement of PLC programmable control are highlighted, deepening the understanding and mastery of PLC programmers.

III. Basic Training Circuits for Transparent Hydraulic PLC Control

- Commutation circuit using manual directional valve.

- Locking circuit using neutral function directional valve.

- Locking circuit using hydraulic control check valve.

- Pressure setting circuit.

- Two-stage pressure control circuit.

- Pressure reducing circuit using pressure reducing valve.

- Boosting circuit using booster cylinder.

- Unloading circuit using H-type directional valve.

- Inlet throttling speed control circuit.

- Return oil throttling speed control circuit.

- Commutation and speed control circuit of speed-regulating gear pump.

- Composite speed control circuit composed of speed-regulating gear pump and speed control valve.

- Speed switching circuit with short-circuited flow valve.

- Secondary feed circuit with series speed control valves.

- Secondary feed circuit with parallel speed control valves.

- Sequential action circuit using sequence valve.

- Sequential action circuit using pressure relay.

- Sequential action circuit controlled by travel switch.

- Sequential action circuit using travel directional valve.

- Synchronous circuit of series hydraulic cylinders.

- Commutation circuit controlled by pilot-operated relief valve.

- Pressure maintaining circuit using check valve.

- Pressure maintaining circuit using directional valve.

- Learning and use of PLC programming software.

- Communication between PLC and computer, online debugging and monitoring.

- Training of basic hydraulic circuits controlled by PLC (optimized control).

V. List of Transparent Hydraulic Training Devices

| 일련 번호 | 이름 | Model | 수량 | 비고 |

|---|---|---|---|---|

| 1 | Training desk | 1500×700×1750mm | 1 piece | – |

| 2 | Training platform | – | 1세트 | – |

| 3 | PLC host module | FX1S-20MR | 1 piece | – |

| 4 | Power module | – | 1 piece | – |

| 5 | Relay control module | – | 1 piece | – |

| 6 | Time relay module | – | 1 piece | – |

| 7 | Control button module | – | 1 piece | – |

| 8 | DC motor | Pump station | 1세트 | – |

| 9 | Special speed control module for DC motor | – | 1 piece | – |

| 10 | Digital tachometer and speed sensor | – | 1 piece | – |

| 11 | Gear oil pump | CB-B6 | 1 piece | – |

| 12 | Relief valve | – | 1 piece | – |

| 13 | Shock-resistant pressure gauge | – | 1 piece | – |

| 14 | Oil tank | – | 1 piece | – |

| 15 | Oil suction filter | – | 1 piece | – |

| 16 | Air filter | – | 1 piece | – |

| 17 | Oil temperature and level gauge | – | 1 piece | – |

| 18 | Double-acting oil cylinder (with stroke stop block) | Transparent component | 2 pieces | – |

| 19 | 2-position 2-way solenoid directional valve | Transparent component | 1 piece | – |

| 20 | 2-position 4-way solenoid directional valve | Transparent component | 2 pieces | – |

| 21 | 3-position 4-way solenoid directional valve (Type O) | Transparent component | 1 piece | – |

| 22 | 3-position 4-way solenoid directional valve (Type H) | Transparent component | 1 piece | – |

| 23 | 3-position 4-way solenoid directional valve (Type M) | Transparent component | 1 piece | – |

| 24 | Spring return oil cylinder | Transparent component | 1 piece | – |

| 25 | Booster cylinder | Transparent component | 1 piece | – |

| 26 | Auxiliary oil tank | Transparent component | 1 piece | – |

| 27 | Check valve | Transparent component | 2 pieces | – |

| 28 | Hydraulic control check valve | Transparent component | 2 pieces | – |

| 29 | Relief valve (direct-acting type) | Transparent component | 2 pieces | – |

| 30 | Relief valve (pilot-operated type) | Transparent component | 1 piece | – |

| 31 | Throttle valve (direct-acting type) | Transparent component | 1 piece | – |

| 32 | Speed control valve | Transparent component | 2 pieces | – |

| 33 | Sequence valve | Transparent component | 2 pieces | – |

| 34 | Pressure reducing valve | Transparent component | 1 piece | – |

| 35 | 2-position 4-way travel directional valve | Transparent component | 1 piece | – |

| 36 | 3-position 5-way manual directional valve | Transparent component | 1 piece | – |

| 37 | Pressure relay | Transparent component | 1 piece | – |

| 38 | Pressure gauge | Transparent component | 3 pieces | – |

| 39 | Three-way joint | Transparent component | 7 pieces | – |

| 40 | Four-way joint | Transparent component | 3 pieces | – |

| 41 | Travel switch | – | 4 pieces | – |

| 42 | Transparent hydraulic hose | – | 20 meters | – |

| 43 | Oil pan | – | 1 piece | – |

| 44 | Hydraulic oil | L-HL46 | 15L | – |

| 45 | 프로그래밍 케이블 | Mitsubishi | 1 piece | – |

| 46 | National standard power cord | – | 1 piece | – |

| 47 | Experimental wires | – | 1 package | – |

| 48 | Quick oil connector | – | 5 pieces | – |

| 78 | Toolbox | – | 1 piece | – |

| 79 | Hex key wrench | – | 3 pieces | – |

| 80 | Screwdriver | – | 2 pieces | – |

| 81 | Scissors | – | 1 piece | – |

| 82 | Adjustable wrench | – | 1 piece | – |

| 83 | Needle-nose pliers | – | 1 piece | – |

| 84 | Hydraulic training manual | – | 1 volume | – |

| 85 | PLC programming software and programs | CD | 1 disc | – |