- Overview

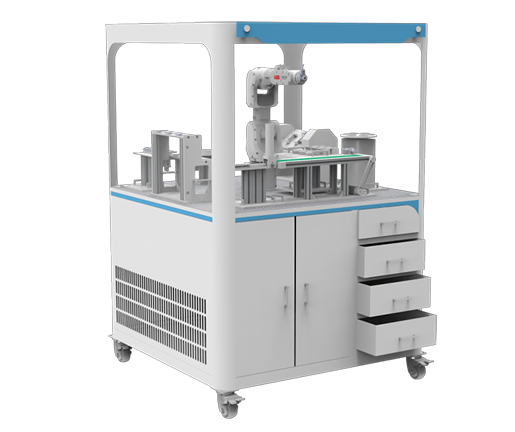

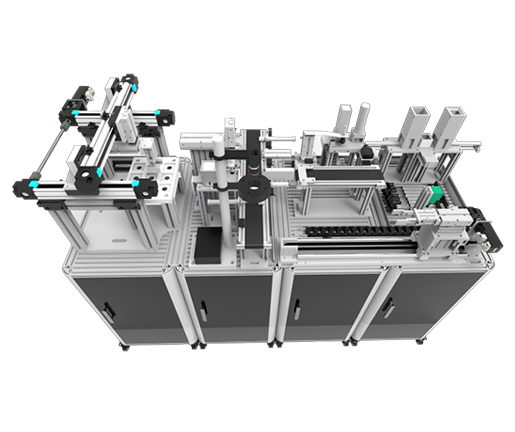

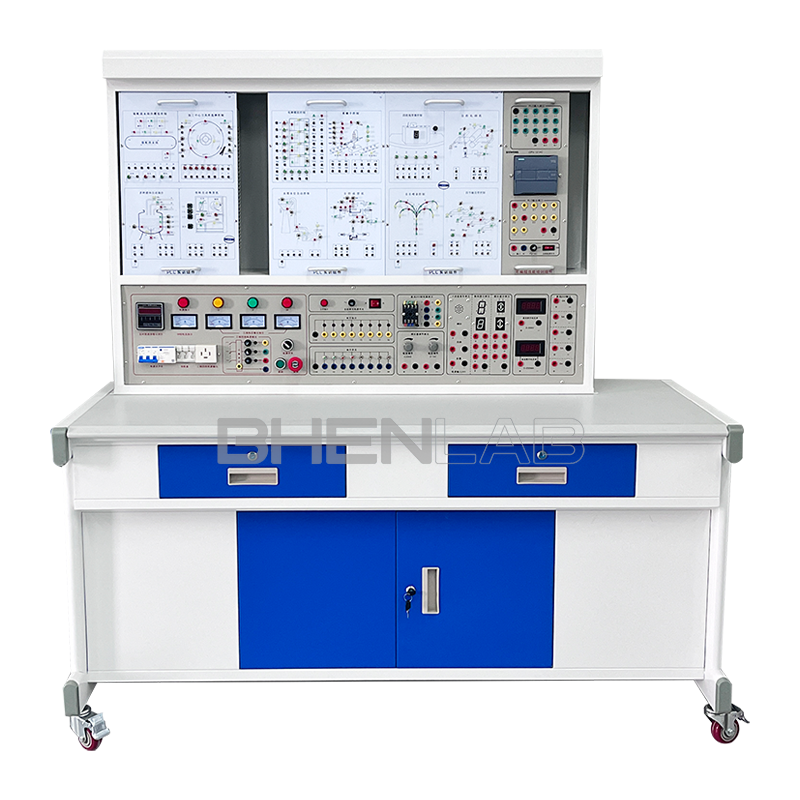

The device is mainly composed of a training desk, a mesh plate, and training components. Students can reasonably layout the components according to the training circuit, and complete the installation and wiring by themselves, which is close to the industrial site. It can complete comprehensive training such as simulation operation, installation and commissioning of machine tool circuits, motor control circuits, and lighting power distribution, so as to train students’ practical ability and operational skills. Training projects can be determined independently, and corresponding components can be selected according to the selected projects. The device can also be used as an assessment equipment for electrician skill examinations.

- Features

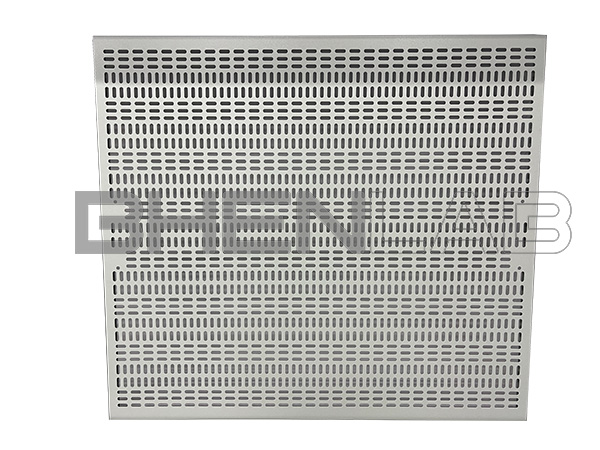

1.The components of the electrical control circuit are all mounted on the mesh plate, which is convenient for operation, easy to replace, and easy to expand functions or develop new training projects (additional training projects can be added by purchasing additional components).

2.The operation platform can be put into use only with a three-phase four-wire AC power supply, which covers a small area, saves training rooms, reduces infrastructure investment, and has significant economic benefits.

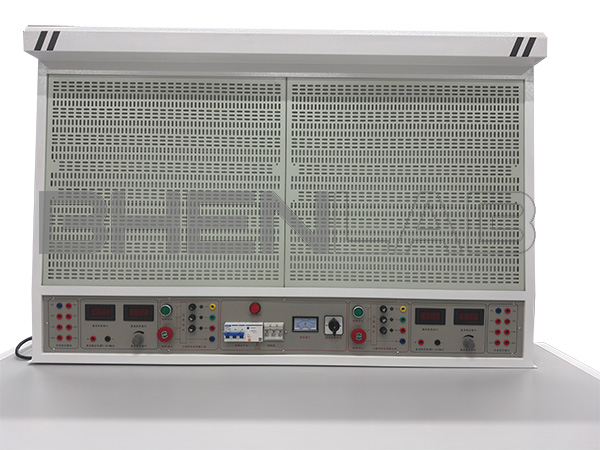

3.The training bench is equipped with two sets of independent power supplies, which do not interfere with each other, so that two students can carry out training at the same time.

4.It is equipped with voltage-type leakage protector and current-type leakage protector to ensure the safety of operators. The power output is equipped with monitoring and short-circuit protection functions, which makes the use safe and reliable.

III. Technical Performance

1.Input power supply: three-phase four-wire system ~ 380V±10% 50Hz

2.Temperature: -5℃~+40℃, relative humidity < 85% (at 25℃)

3.Device capacity: < 1.5KVA

4.Overall dimensions: 1600mm×700mm×1690mm

- Configuration of the Training Bench

1.Public part: Equipped with voltage-type leakage protection and current-type leakage protection. The external power input is indicated by an indicator light. An emergency stop button is provided. In case of emergency, press the button to cut off the main power supply of the training bench.

2.Each group is provided with two types of power supplies: line voltage 380V or phase voltage 220V, a single-phase power socket, and a line voltage input indicator.

3.Each group is provided with 3V, 6V, 9V, 12V, 18V, 24V, 36V low-voltage AC power supplies.

4.Each group is provided with a constant current and regulated power supply with a voltage of 0-30V and a maximum current of 3A. It has a built-in relay for automatic shifting, a multi-turn potentiometer for continuous adjustment, and a digital meter to indicate current and voltage values.

5.The training desk is of iron double-layer matte dense-grained spray structure. The desktop is a fireproof, waterproof and wear-resistant high-density board. The structure is firm, and the shape is beautiful and generous. There are drawers on the left and right sides of the desk, and a component storage cabinet at the lower part.

- Reference Training Projects

| 1. Electrical wiring process training 2. Training on the circuit of controlling a lamp with two switches 3. Training on the incandescent circuit controlled by an acoustic switch 4. Training on the circuit of controlling a lamp in two places 5. Training on the circuit of controlling a lamp in three places 6. Training on wiring of fluorescent lamp circuit 7. Direct installation and wiring of single-phase watt-hour meter 8. Installation and wiring of single-phase watt-hour meter through current transformer 9. Installation training of indoor lighting circuit 10. Installation training of distribution board 11. Measurement of AC load power 12. Direct start control of three-phase asynchronous motor |

13. Contactor inching control circuit of three-phase asynchronous motor 14. Contactor self-locking control circuit of three-phase asynchronous motor 15. Y/△ automatic control circuit of three-phase asynchronous motor 16. Circuit of controlling forward and reverse rotation of three-phase asynchronous motor with forward-reverse switch 17. Forward and reverse interlocking control circuit with contactor 18. Forward and reverse control circuit of three-phase asynchronous motor with button interlocking 19. Double interlocking forward and reverse control circuit of three-phase asynchronous motor 20. Multi-location control of three-phase asynchronous motor 21. Automatic round-trip control circuit of workbench 22. Reduced-voltage starting control circuit of three-phase asynchronous motor with series resistance 23. Energy consumption braking control circuit of three-phase asynchronous motor |

- List of Components Required for Reference Training Projects

| 일련 번호 | 이름 | Model and Specification | 수량 |

| 1 | Single-phase watt-hour meter | DD862-2 | 1 |

| 2 | Single-phase knife switch | HK8 | 1 |

| 3 | Pull switch | 4A/250V | 1 |

| 4 | Flat lamp holder | 6A/250V | 2 |

| 5 | Circular socket | T3-10 | 1 |

| 6 | Current transformer | LQG-0.5 | 1 |

| 7 | Wall switch base | 2 | |

| 8 | Acoustic switch | 118-B30 | 1 |

| 9 | Low-voltage circuit breaker | DZ108-20/10 | 1 |

| 10 | Spiral fuse box | RL1-15/3A | 3 |

| 11 | In-line fuse box | RT14-20/2A | 2 |

| 12 | AC contactor | CJX2-0910 | 3 |

| 13 | Auxiliary contact | F4-22 | 3 |

| 14 | Thermal relay | R16B-20/3 | 1 |

| 15 | Power-on delay time relay | ST3PA-B/380V (0-60S) | 1 |

| 16 | Time relay base | PF-083A | 1 |

| 17 | 3H iron shell button | 2 | |

| 18 | Travel switch | LX9-222 | 2 |

| 19 | Travel switch | LX9-001 | 2 |

| 20 | Forward-reverse switch | K03-15 | 1 |

| 21 | Fluorescent tube | Y210RR25/10W | 1 |

| 22 | Ballast | 13W | 1 |

| 23 | Fluorescent lamp holder | 2 | |

| 24 | High-power resistor | 3 | |

| 25 | Diode | 1 | |

| 26 | Terminal block | JF5-2.5/5 | 5 |

| 27 | G-type guide rail | 1 | |

| 28 | Wire trough | 2 meters | |

| 29 | Screw | 90 | |

| 30 | Screwdriver | 2 | |

| 31 | Long-nose pliers | 1 | |

| 32 | Wire stripper | 1 | |

| 33 | Three-phase squirrel-cage asynchronous motor | 380V/Y/△180W | 1 |

| 34 | Siemens SR30 | 1 | |

| 35 | Siemens V20 inverter | 1 |