Training Content:

The modular flexible automated production training system provides a teaching and training platform for comprehensive application design, covering knowledge in mechanical, electrical, and pneumatic integration. The specific contents are as follows:

- Sensor Application Technology Training

The system uses various types of sensors, including inductive sensors, photoelectric sensors, electromagnetic sensors, capacitive sensors, diffuse reflection sensors, etc. Each sensor’s connecting wire is distinguished by marks, numbered, and connected to the open controller through a unified plug type. It also comes with user manuals and wiring diagrams for different sensors, allowing students to fully master the usage methods, working modes in the system, and precautions for various industrial sensors.

- Pneumatic Technology Training

The device uses a large number of pneumatic components, including various electric-controlled pneumatic valves, cylinders, pneumatic grippers, vacuum suction cups, vacuum generators, filter pressure regulating valves, etc. Students can learn how various pneumatic components coordinate with other components to work. All interfaces and control lines of each component are connected externally in an open manner, enabling students to fully master the usage methods of each component, understand their working performance in the production process, and precautions during use.

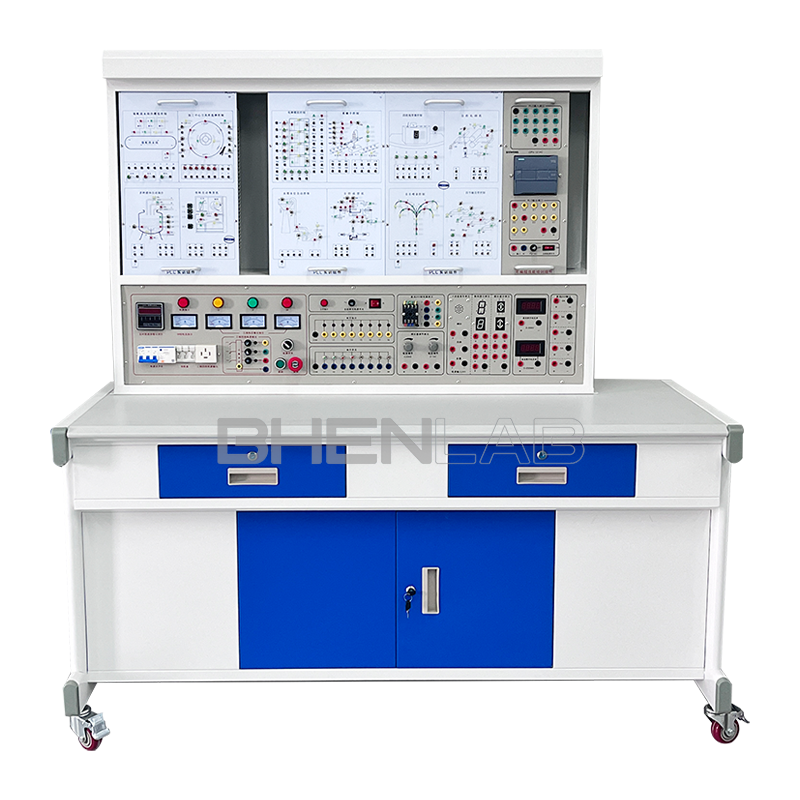

- PLC Technology Training

Each station in the system has its own set of PLC controllers, which can be arbitrarily connected to various components with plugs. The stations are connected via RS485 N:N communication for distributed control. On this equipment, students can not only learn various PLC software programming technologies, hardware port connection technologies, PLC communication technologies but also learn multiple application methods of PLC in a comprehensive technological environment. It provides conditions for students to flexibly learn and master various aspects of PLC knowledge. The integrated open ports can be easily connected to components in each execution system, with simple and clear wiring.

- Electrical Control System Training

The electrical control part of the system is designed in accordance with industrial standards and habits. All sensor wiring ports are marked and connected externally in a plug-in manner, and all design drawings and manuals are provided as attachments. Students can learn circuit schematic analysis, PLC I/O address checking, and new equipment circuit connection design analysis methods on this device according to the design drawings.

- Mechanical System Installation and Commissioning Training

The system allows each group of students to disassemble the mechanical part, reassemble it as required, and debug it until the system works normally, which is of great help to improve the practical ability of 在校 students. The mechanical part of the system adopts a mobile design, allowing students to reconfigure mobile modules into various systems with different processes.

- Motor Drive Technology Training

The system is equipped with multiple sets of stepping motors and motor driver systems, including dual-axis and single-axis modes. It is also equipped with a set of frequency conversion speed regulation modules and other various motors. Each driver is controlled by PLC I/O digital signals, enabling students to fully learn the characteristics of various drivers for different motors. Each module driver can be tested independently, providing sufficient practice opportunities for students.

- System Maintenance and Fault Detection Technology Training

This part of the training focuses on introducing the content and methods of daily maintenance of mechatronic systems, as well as the methods of analyzing and troubleshooting common system faults.

- Computer Configuration Monitoring Technology Training

The system adopts typical domestic popular industrial control configuration monitoring software (such as KingView/CGS, etc.). Through learning this software, students can understand the basic structure of communication networks, the basic framework of configuration monitoring software, the basic usage methods of configuration software, and learn about common problems and handling methods in actual engineering.

- Network Technology Training

Each unit of the system can work completely independently. Students can write PLC programs for each unit according to control requirements, debug them to normal operation, and then connect multiple units into a complete modern production logistics system through network technology. With the addition of network hardware modules, the control requirements include the link of data exchange and processing between PLCs of each unit, increasing the content of learning PLC network communication and providing convenient training conditions for mastering relevant knowledge.

Equipment Composition:

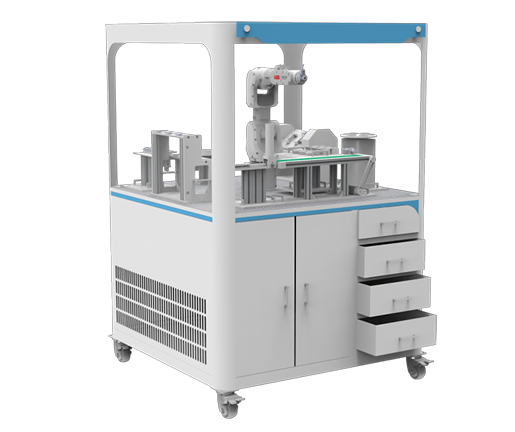

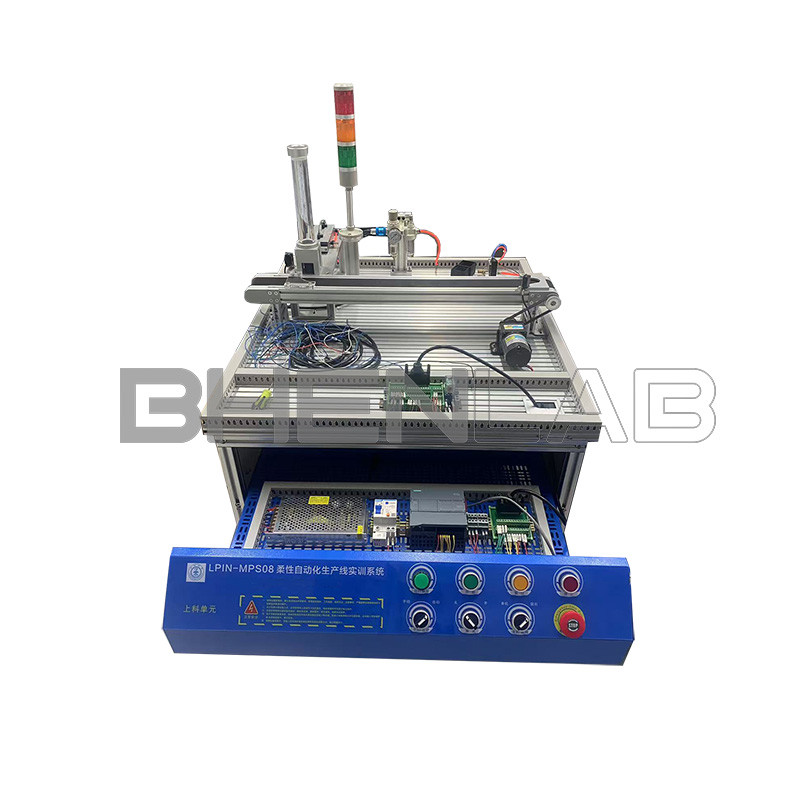

(1) Feeding and Detection Unit

It automatically sends the workpieces to be processed placed in the silo to the conveyor belt as needed, distinguishes the color of the workpieces to be processed through a color detection device, and conveys the workpieces to the discharge position via the conveyor belt, so that the grabbing manipulator device of the servo manipulator unit can grab the workpieces and send them to other working units for the next process. The discharge of this device is stable and meets the time required for students’ disassembly and debugging.

Technical Indicators: Size (length × width × height): 800mm × 1000mm × 1500mm

Mechanical part:

- Metal cart with 4 universal wheels

- 20 × 80 aluminum profile tabletop

- Metal electrical hanging board

- Well-type storage silo

- Automatic pushing device

- Conveyor belt mechanism

- Automatic intercepting color detection mechanism

- Acousto-optic alarm device

Control components:

- PLC: Siemens 1212C with communication module and programming cable

- Switching power supply: AC 220V input, DC 24V/4.5A output

- Button control panel: 8 buttons

- Photoelectric sensors for detecting workpieces and colors

- Two sets of electric-controlled pneumatic valves and their actuators

- Driven by DC24V gear reduction motor

- 1 filter regulator combination

(2) Handling Unit

This unit mainly completes the grabbing and handling of workpieces, responsible for transporting the workpieces from the discharge position of the feeding and detection unit to the feeding position of the processing unit.

Technical Indicators: Size (length × width × height): 800mm × 1000mm × 1500mm

Mechanical part:

- Metal cart with 4 universal wheels

- 20 × 80 aluminum profile tabletop

- Small pneumatic manipulator

- Pneumatic telescopic cross arm

- Rotary table driven by AC servo motor and worm gear reducer

- Manipulator claw

- Metal electrical hanging board

Control components:

- PLC: Siemens 1212C with communication module and programming cable

- Pneumatic gripper

- Double cylinder

- Parallel air gripper

- Lifting cylinder

- Switching power supply module: AC 220V input, DC 24V/4.5A output

- Button control panel: 8 buttons

- Three sets of electric-controlled pneumatic valves and their actuators

- 8-input 8-output, 2 I/O adapter boards

- Filter regulator combination

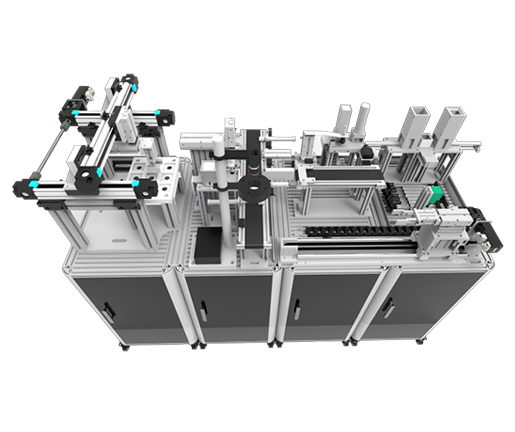

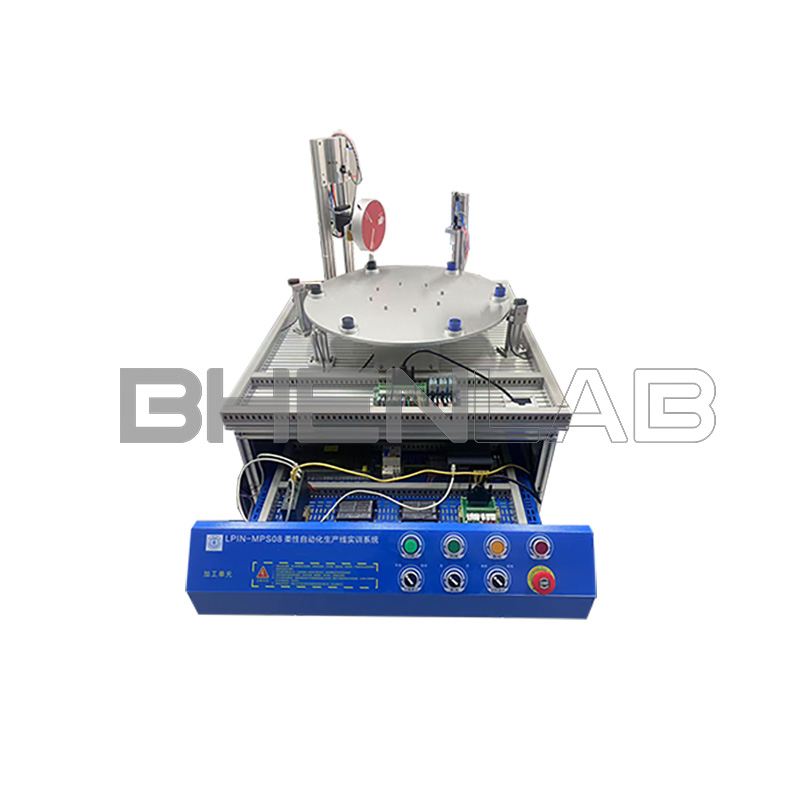

(3) Processing Unit

It mainly completes the processing and depth detection of workpieces. The four-station rotary table transports the workpieces sent from the previous unit to the processing position for processing, then to the detection position for depth detection after processing, and finally to the discharge position to be taken away by the next unit.

Technical Indicators: Size (length × width × height): 800mm × 1000mm × 1500mm

Mechanical part:

- Metal cart with 4 universal wheels

- 20 × 80 aluminum profile tabletop

- Four-station rotary table

- Tool change processing mechanism (controlled by stepping motor)

- Lifting processing system and processing components

- Lifting detection system and detection components

- Metal electrical hanging board

Control components:

- PLC: Siemens 1212C with communication module and programming cable

- Switching power supply: AC 220V input, DC 24V/4.5A output

- Control panel: 8 buttons

- Sensors for detecting workpieces and turntable in place

- Three sets of electric-controlled pneumatic valves and their actuators

- Driven by 24V DC motor and worm gear reducer

- Stepping motor and driver

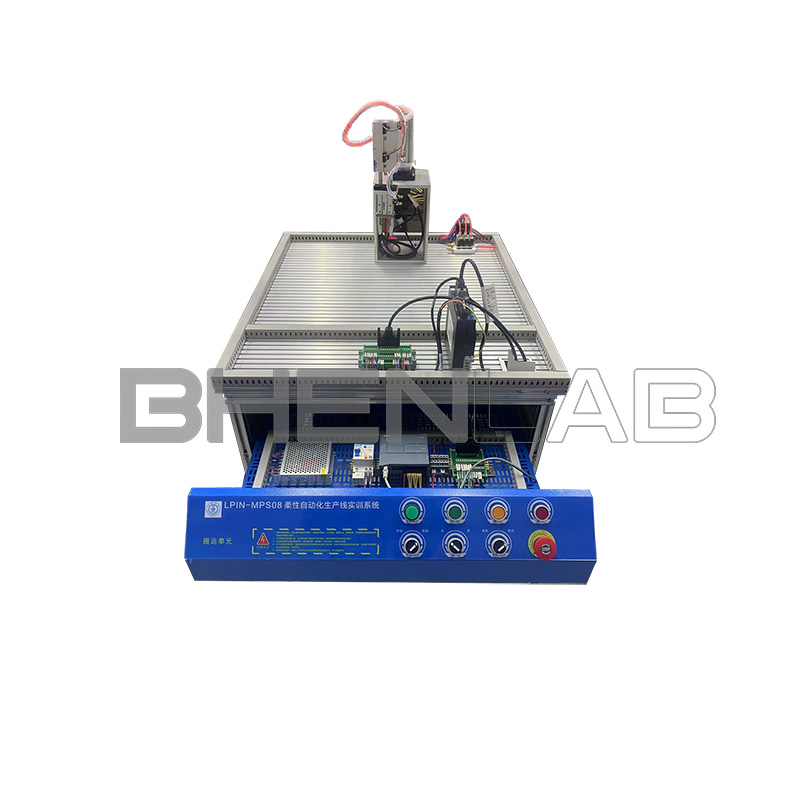

(4) Conveying Unit

The air gripper on the extraction device lifts the workpiece from the previous station and conveys it to the next unit according to the workpiece information results from the previous station. This working unit can be combined with other working units and define other classification standards, and the workpieces can be directly transmitted to the next working unit.

Technical Indicators: Size (length × width × height): 800mm × 1000mm × 1300mm

Mechanical part:

- Metal cart with 4 universal wheels

- 20 × 80 aluminum alloy tabletop

- Linear moving mechanism

- Industrial guide rail

- Metal electrical hanging board

Control components:

- PLC: FX3U-48MR with communication module and programming cable

- Switching power supply: AC 220V input, DC 24V/4.5A output

- Button control panel: 8 buttons

- DC motor

- 2 photoelectric sensors

- 8-input 8-output, 2 I/O adapter boards

- Filter regulator combination

(5) Installation and Handling Unit

The air gripper lifts the workpiece from the previous station and conveys it to the next unit according to the workpiece information results from the previous station. This working unit can be combined with other working units and define other classification standards, and the workpieces can be directly transmitted to the next working unit. This working unit is equipped with an installation position, which can transport the workpiece from the previous station to the installation position for the installation unit to install small workpieces.

Technical Indicators: Size (length × width × height): 800mm × 1000mm × 1400mm

Mechanical part:

- Metal cart with 4 universal wheels

- 20 × 80 aluminum alloy platform

- Manipulator

- Mobile sliding table

- Installation workbench

- Metal electrical hanging board

- Industrial guide rail and bracket

Control components:

- PLC: FX3U-48MR with communication module and programming cable

- Switching power supply: AC 220V input, DC 24V/4.5A output

- Button control panel: 8 buttons

- Parallel air gripper

- Single-rod cylinder

- 2 thin cylinders

- Four sets of electric-controlled pneumatic valves and their actuators

- 8-input 8-output, 2 I/O adapter boards

- Filter regulator combination

(6) Installation Unit

During the feeding process, the double-acting cylinder pushes small workpieces out of the silo one by one, and the rotating arm of the conversion module moves the workpieces to the transmission position of the next working unit under the drive of the rotating cylinder.

Technical Indicators: Size (length × width × height): 800mm × 1000mm × 1500mm

Mechanical part:

- Metal cart with 4 universal wheels

- 20 × 80 aluminum profile tabletop

- Material cylinder

- Material changing mechanism

- Pushing mechanism

- Industrial guide rail and bracket

- Metal electrical hanging board

- Upper and lower rocker arm components

- Vacuum suction cup

Control components:

- PLC: FX3U-48MR with communication module and programming cable

- Switching power supply: AC 220V input, DC 24V/4.5A output

- Button control panel: 8 buttons

- 3 single-rod cylinders

- Vacuum generator

- Four sets of electric-controlled pneumatic valves and their actuators

- 8-input 8-output, 2 I/O adapter boards

- Filter regulator combination

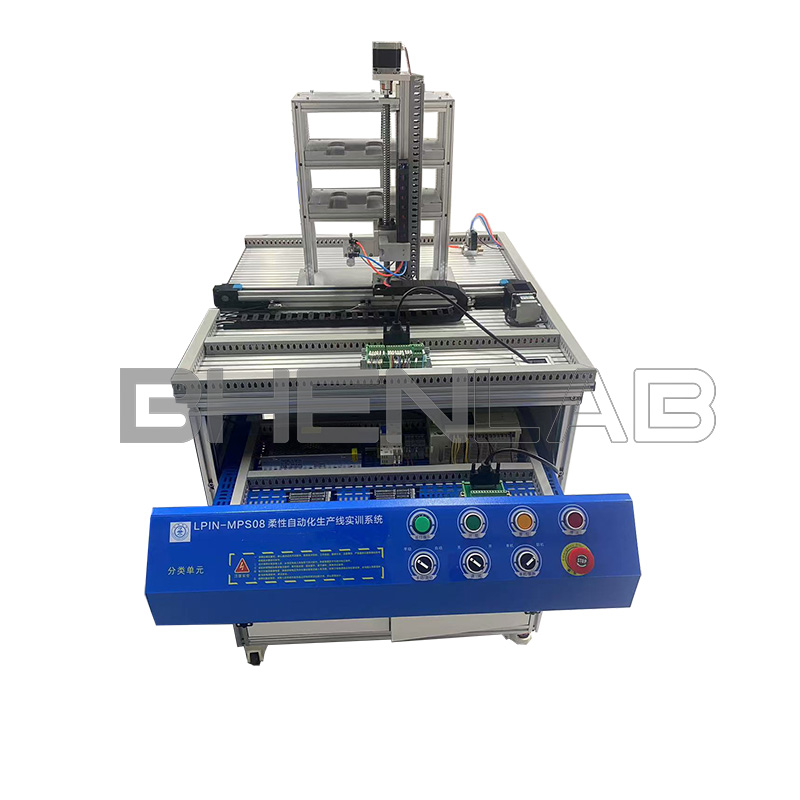

(7) Classification Unit

It classifies the installed workpieces and transports the classified workpieces to the designated warehouse.

Technical Indicators: Size (length × width × height): 800mm × 1000mm × 1300mm

Mechanical part:

- Metal cart with 4 universal wheels

- 20 × 80 aluminum profile tabletop

- Horizontal sliding table, ball screw drive

- Vertical sliding table, ball screw drive

- Pneumatically driven pushing component

- Classification silo

- Metal electrical hanging board

Control components:

- PLC: FX3U-48MR with communication module and programming cable

- Switching power supply: AC 220V input, DC 24V/4.5A output

- Button control panel: 8 buttons

- Single-rod cylinder

- X and Y axis origin sensors (inductive sensors)

- Single electric-controlled pneumatic valve and its actuator

- Stepping motor and driver

- 8-input 8-output, 2 I/O adapter boards

- Filter regulator combination

(8) Touch Screen Monitoring Unit

It is composed of a 7-inch STN 256-color screen, etc., mainly responsible for monitoring the working status of each sub-station, coordinating the operation of each station, and completing the integration of the industrial control network. The bus structure adopts RS485 network communication, enabling real-time exchange of control information and status data between stations. Each station is equipped with a programming cable.

(9) Industrial Configuration Monitoring Software

When all 8 units are in the networked state, the administrator can conveniently control the operation, pause, continue, stop of the entire system through various configuration buttons in the configuration monitoring machine, and also control the operation, pause, continue, stop of a single unit. The working status of each unit, as well as the material and color of the workpieces, can be clearly seen on the monitoring screen.

LPIN-MPS08 Flexible Automated Production Line Training System

タグ: Automated production line equipmentProduction Line Teaching Equipmentカテゴリー: Others, PLCトレーニング機器商品コード: 該当なし

ブランド: ベンラボ