I. Overview

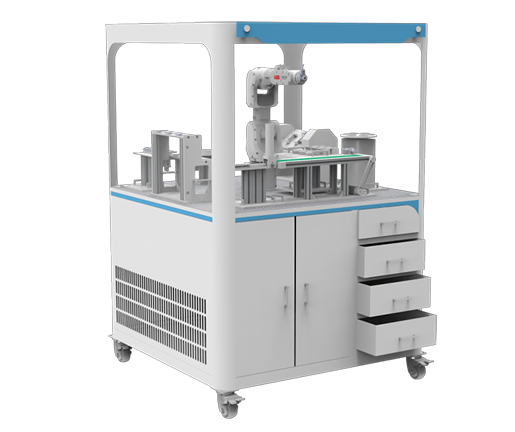

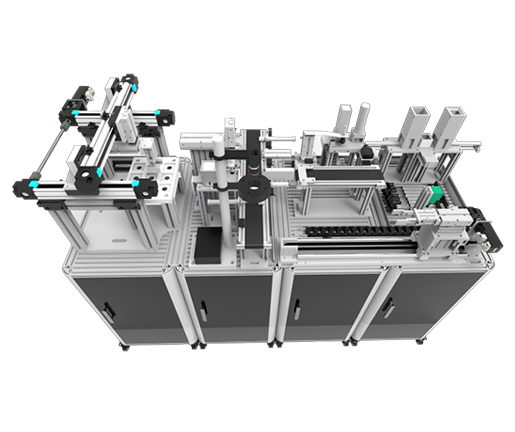

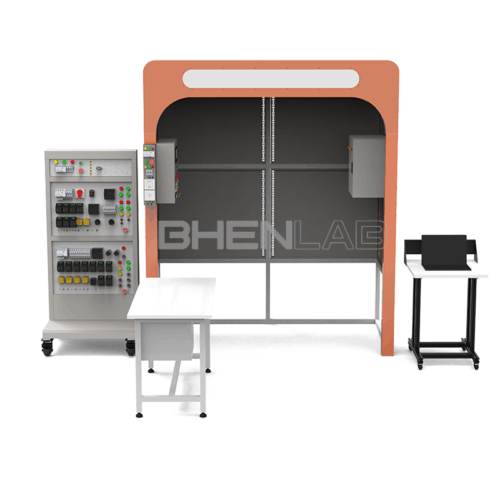

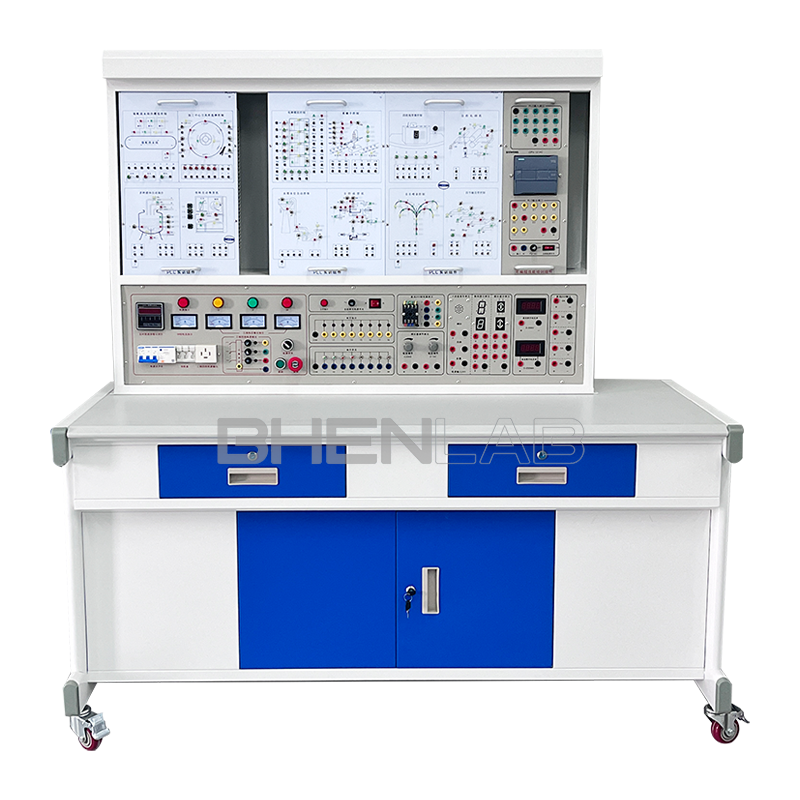

The electrical installation and maintenance training and assessment device is a universal training platform developed in accordance with the training and appraisal requirements for maintenance electricians and electrical installers in factory electrical installation, indoor electrical installation, etc. It is very suitable for various vocational colleges and technical schools as a public platform for maintenance electricians, electrical installers, and other majors with electrical installation requirements. It is composed of steel mesh panels and special steel profiles, equipped with self-locking casters for easy movement and use. The surface of the device is spray-painted with a stable color. The device is equipped with a dedicated power supply station. The design height of the device allows convenient operation when a person stands on a one-step stepladder, which is safe and enables users to experience the construction site environment. The horizontal and vertical widths are appropriate, which can simulate the steering arrangement of on-site lines. The mesh panel can be easily removed. To facilitate the construction of concealed works, the industrial aluminum profile frame imitates building partitions with pipe 穿 holes, and cable ties are used to fix the conduit. When passing through the mesh panel, wall bushings can be used to lead wires into the surface-mounted junction box. The supporting PVC pipe bender can easily bend the PVC pipe into 90 degrees. Electrical installation can be carried out, such as bridge installation, PVC pipe installation, chandeliers, incandescent lamp holders, fluorescent lamps, switches, sockets, distribution boxes, control boxes, etc. The device also includes AC asynchronous motors, DC motors, stepper motors, temperature controllers, thermocouples, PLC, inverter touch screens, and other control and controlled objects. Each operation group of the system is equipped with a mobile tool cart and a component cabinet, which is convenient for the storage and installation of components. It fundamentally solves the problems of inconvenient use and narrow training scope in school installation training conducted on ordinary walls. It has the characteristics of flexible and convenient assembly. According to the actual teaching conditions of the school, it can be formed into 2-person groups, single-sided, and multi-angle combinations based on 2 basic combination units of 0.8 meters, supplemented by combination units of 0.2 meters and 0.4 meters to form different length combinations to meet different teaching venues. It can provide training and assessment for various post groups with electrical installation requirements such as hydropower installers.

II. Configuration

(1) Device structure size: 2-person group training equipment (single-sided): 2006mm in length × 1003mm in width × 2410mm in height

Other reference dimensions of structures

2-person group training equipment (single-sided): 2006mm in length × 1003mm in width × 2410mm in height

Configuration List

- Distribution Box Part

| Serial Number | Name | Specification/Model | Unit | Quantity | Remarks (Description) |

| 1 | Three-phase four-wire active energy meter | DT864 | Piece | 1 | |

| 2 | Isolating switch | HG1-32/30F | Set | 1 | |

| 3 | Button label frame | Piece | 3 | ||

| 4 | Aluminum alloy mounting rail | HR-5600A | Strip | 1 | Length: 210 mm |

| 5 | Indicator light | AD58B-22D 220V | Piece | 3 | 1 each of red, green and yellow |

| 6 | Distribution box body | 450mm×220mm×520mm | Piece | 1 | Including grounding bar and neutral bar |

| 7 | Mounting screws | Piece | Several | ||

| 8 | Residual current operated circuit breaker | 3P+N D10A | Piece | 1 | |

| 9 | Residual current operated circuit breaker | 3P+N D16A | Piece | 1 | |

| 10 | Residual current operated circuit breaker | 1P+N C20A | Piece | 1 | |

| 11 | Residual current operated circuit breaker | 1P+N C16A | Piece | 1 | |

| 12 | Air switch | 3P D20A | Piece | 1 | |

| 13 | Air switch | 3P D25A | Piece | 1 |

- Lighting Kit

| Serial Number | Name | Model and Specification | Unit | Quantity | Remarks (Description) |

| 1 | Fluorescent tube | 18W | Piece | 1 | |

| 2 | Energy-saving lamp | 9W | Piece | 2 | |

| 3 | Edison screw socket | E27 | Piece | 2 | |

| 4 | Acousto-optic control automatic switch | 86 type | Piece | 1 | |

| 5 | One socket | 118 type | Piece | 1 | |

| 6 | Two sockets | 118 type | Piece | 1 | |

| 7 | One switch | 118 type | Piece | 1 | |

| 8 | Two switches | 86 type | Piece | 2 | |

| 9 | One switch | 86 type | Piece | 2 | |

| 10 | One socket | 86 type | Piece | 2 | |

| 11 | Touch switch | 86 type | Piece | 1 | |

| 12 | Three-pole earthed plug | Piece | 1 | ||

| 13 | One-position blank plate | 86 type | Piece | 2 | |

| 14 | Plastic round wood | YM-2 | Set | 1 | 4 inches, material: PVC |

| 15 | Surface-mounted box | 86 type | Piece | 4 | |

| 16 | Surface-mounted box | 118 type | Piece | 3 | |

| 17 | Surface-mounted box | 86 type, deepened | Piece | 2 | |

| 18 | Electronic lamp holder | 20W | Piece | 1 | |

| 19 | Surface-mounted distribution box | PZ30-15 | Piece | 1 | |

| 20 | Residual current air switch | 1P+N C10A | Piece | 2 | |

| 21 | Residual current air switch | 1P+N C16A | Piece | 2 | |

| 22 | Air switch | 1P C6A | Piece | 2 | |

| 23 | Air switch | 1P C10A | Piece | 2 | |

| 24 | Air switch | 2P C32A | Piece | 1 |

- Electrical Control Box

| Serial Number | Name | Specification/Model | Unit | Quantity | Remarks (Description) |

| 1 | Molded case circuit breaker | Chint NM1-63S/3300T 20A 3P | Piece | 1 | |

| 2 | Contactor | CJX2-0910/220V | Piece | 5 | |

| 3 | Auxiliary contact | F4-22 | Piece | 4 | |

| 5 | Programmable controller | H2U-1616MT-XP | Piece | 1 | |

| Expansion module | H2U-0016ERN | Piece | 1 | ||

| 6 | Inverter | MD280NT 0.7GB | Piece | 1 | |

| 78 | Time relay | ST3PF-2 30S | Piece | 1 | |

| ST3P C-A 30S | Piece | 1 | |||

| 9 | Thermal relay | NR2-25 (with mounting base) | Piece | 3 | 2 pieces of 0.4A (adjustment range 0.25~0.4A), 1 piece of 0.63A (adjustment range 0.4~0.63A) |

| 10 | Temperature controller (Omron temperature controller) | E5CC-RX2ASM-800 | Piece | 1 | |

| 11 | Terminal block | TB-1512 | Strip | 2 | |

| 12 | Switching power supply | YL-061 | Piece | 1 | For touch screen |

| 13 | Touch screen | TPC7062KX | Piece | 1 | 7-inch color screen |

| 14 | Mounting rail | FL-3514A | Strip | 1 | |

| 15 | Mounting screws | M3×20 | Set | 20 | |

| M3×16 | Piece | 20 | |||

| M4×20 | Set | 20 | |||

| 16 | Control box body | 700mm×240mm×500mm | Piece | 1 | Including grounding bar and neutral bar |

| 17 | Button | LA68B-EA35/45 | Piece | 10 | 5 each for start and stop (red, green)Equipped with 1 emergency stop button |

| Emergency stop switch | LA68-ES542(B2-ES542) | Piece | 1 | ||

| 18 | Indicator light | AD58B-22D 220V | Piece | 5 | Red |

| 19 | Sign plate | Piece | 25 | For indicator light and switch identification | |

| 20 | Selector switch | SB2-ED33 | Piece | 2 | 3-position switch |

| SB2-ED25 | Piece | 2 | 2-position switch | ||

| 21 | Data cable | PLC communication cable | Strip | 1 | |

| Touch screen download cable | Strip | 1 |

- Motor Module

| Serial Number | Name | Specification/Model | Specification/Model | Unit | Quantity | Remarks (Description) |

| 1 | Three-phase AC asynchronous motor | YS5024(Y-△) | YS5024(Y-△) | Piece | 1 | See motor base list |

| 2 | Three-phase AC asynchronous motor | YS5024(Y-△) with centrifugal switch | YS5024(Y-△) with centrifugal switch | Piece | 1 | |

| 3 | Three-phase AC asynchronous motor (two-speed 60W) | YS5012/4 two-speed motor | YS5012/4 two-speed motor | Piece | 1 | |

| 4 | Separately excited DC motor | DC110V/50W | DC110V/50W | Piece | 1 | |

| 5 | Motor unit bracket | 330mm×205mm×65mm | 330mm×205mm×65mm | Set | 2 | |

| 6 | Switching power supply | YL-012(24V/5V/2A/2A) | YL-012(24V/5V/2A/2A) | Piece | 1 | For stepper driver |

| 7 | Two-phase hybrid stepper motor | Driver | SH-20403 | Piece | 1 | |

| Motor | 42BYGH5403(AA) | |||||

| 8 | AC servo motor | Driver | ASD-B2-0421-B | Piece | 1 | Delta servo |

| Motor | ECMA-C20604RS |

- Sensor Module

| Serial Number | Name | Specification/Model | Unit | Quantity | Remarks (Description) |

| 1 | Travel switch | YBLX-ME/8104 | Piece | 4 | |

| 2 | Capacitive sensor | ODR-D05NK | Piece | 1 | |

| 3 | Inductive sensor | OBM-D07NK | Piece | 1 | |

| 4 | Photoelectric sensor | JG-3D-30NK | Piece | 1 | |

| 5 | Temperature sensor | Pt100 | Piece | 1 | |

| Temperature experiment module | YLCG2004-09B | Block | 1 | ||

| 6 | Protective coil | ¢4 | Piece | 4 | |

| 7 | Terminal block | HF-1.5/13 | Strip | 1 | |

| HF-1.5/8 | Strip | 2 | |||

| 8 | Conductor | BVR-0.5 m㎡ | Meter | 2.8 | 1.4 meters each for yellow and green |

| 9 | Screw | M4×20 | Set | 8 | |

| M3×30 | Set | 16 |

Line Equipment

| Serial Number | Name | Name | Specification/Model | Specification/Model | Unit | Quantity | Remarks (Description) |

| 1 | PVC conduit | PVC conduit | Φ16 Type A | Φ16 Type A | Root | 3 | 3m |

| Φ20 Type A | Φ20 Type A | Root | 2 | 3m | |||

| 2 | PVC wall bushing | PVC wall bushing | Φ16 | Φ16 | Piece | 20 | |

| Φ20 | Φ20 | Piece | 20 | ||||

| 3 | U-type flat head pipe clamp | U-type flat head pipe clamp | Φ16 | Φ16 | Piece | 30 | |

| Φ20 | Φ20 | Piece | 30 | ||||

| 4 | PVC trunking | PVC trunking | 20×10 Type A | 20×10 Type A | Root | 2 | |

| 40×20 Type A | 40×20 Type A | Root | 2 | ||||

| 60×40 Type A | 60×40 Type A | Root | 2 | ||||

| 5 | PVC trunking end cap | PVC trunking end cap | 20×10 | 20×10 | Piece | 2 | |

| 40×20 | 40×20 | Piece | 2 | ||||

| 60×40 | 60×40 | Piece | 2 | ||||

| 6 | Trunking | Trunking | 25×30 | 25×30 | Root | 2 | 2m/root |

| 7 | Insulated conductor | Insulated conductor | RV1.5 mm2 | RV1.5 mm2 | Reel | 1 | Red |

| RV1.5 mm2 | RV1.5 mm2 | Reel | 1 | Yellow-green 双色 | |||

| RV2.5 mm2 | RV2.5 mm2 | Reel | 1 | Yellow-green 双色 | |||

| RV0.75 mm2 | RV0.75 mm2 | Reel | 3 | 2 reels of black, 1 reel of blue | |||

| BV2.5 mm2 | BV2.5 mm2 | Reel | 5 | 1 reel each of yellow, green, red, blue and 双色 | |||

| BV1.5 mm2 | BV1.5 mm2 | Reel | 3 | 1 reel each of red, blue and 双色 | |||

| 8 | Five-core cable | Five-core cable | RV5*0.75 mm2 | RV5*0.75 mm2 | M | 10 | |

| 9 | Three-pole earthed plug | Three-pole earthed plug | K-88 | K-88 | Piece | 1 | 16A |

| 10 | U-type insulated terminal | U-type insulated terminal | SV1.25-4 | SV1.25-4 | Piece | 1000 | Red |

| SV2-5L | SV2-5L | Piece | 500 | Blue | |||

| 11 | Tubular insulated terminal | Tubular insulated terminal | E-1008 | E-1008 | Piece | 1000 | Black |

| TE1008 / 双线插针 | TE1008 / 双线插针 | Piece | 1000 | Black

|

|||

| 12 | Wrapping tape | Wrapping tape | Φ10 | Φ10 | Package | 1 | 10m/package |

| 13 | Cable tie | Cable tie | 3×100mm | 3×100mm | Package | 1 | 500 pieces/package |

| 14 | Special-shaped number tube | Special-shaped number tube | 1.5mm2 | 1.5mm2 | Roll | 1 | White |

| 15 | Wire and cable protection hose | Wire and cable protection hose | Φ20 | Φ20 | M | 4 | Black |

| 16 | Wire and cable protection hose | Wire and cable protection hose | Φ16 | Φ16 | M | 4 | Black |

| 17 | Protection hose joint | Protection hose joint | Φ20 | Φ20 | Piece | 2 | Black |

| 18 | Protection hose joint | Protection hose joint | Φ16 | Φ16 | Piece | 2 | Black |

| 19 | Self-tapping screw | Self-tapping screw | Φ6×15 | Φ6×15 | Piece | 200 | Mounting screws, with several flat washers and spring washers |

| Φ6×25 | Φ6×25 | Piece | 60 | ||||

| 20 | Grounding bar | Grounding bar | 5-hole | 5-hole | Strip | 4 | Special (external grounding main line) |

| 21 | Plastic insulating tape | Plastic insulating tape | Reel | 1 | Black | ||

| 22 | Protective coil | Protective coil | Matching Φ30 hole | Matching Φ30 hole | Piece | 10 | For distribution box and electrical box |

| Matching Φ25 hole | Matching Φ25 hole | Piece | 4 | For lighting distribution box | |||

| Matching Φ8 hole | Matching Φ8 hole | Piece | 2 | For fluorescent lamp opening | |||

| 23 | Metal bridge (with cover) | Bridge | 1 | 50×30×500 | Root | 4 | 500mm/root |

| 2 | 50×30×300 | Root | 4 | 300mm/root | |||

| 3 | 50×30×200 | Root | 4 | 200mm/root | |||

| 4 | 50×30×150 | Root | 4 | 150mm/root | |||

| Accessory 1 | Horizontal 90° bend100×100×30mm | Horizontal 90° bend100×100×30mm | Piece | 4 |  | |||||||

| Accessory 2 | Horizontal 45° bend100×100×30mm | Horizontal 45° bend100×100×30mm | Piece | 4 | |||

| Accessory 3 | Horizontal tee100×100×30mm | Horizontal tee100×100×30mm | Piece | 2 |  | |||||||

| Accessory 4 | Bridge with hole head(end face) aperture Φ23 | Bridge with hole head(end face) aperture Φ23 | Piece | 4 |  | |||||||

| Accessory 5 | Horizontal cross100×100×30mm | Horizontal cross100×100×30mm | Piece | 2 |  | |||||||

| Accessory 6 | Vertical equal diameter downward bend (internal corner)100×100×30mm | Vertical equal diameter downward bend (internal corner)100×100×30mm | Piece | 2 |  | |||||||

| Accessory 7 | Vertical equal diameter upward bend (external corner)100×100×30mm | Vertical equal diameter upward bend (external corner)100×100×30mm | Piece | 2 |  | |||||||

| Accessory 8 | Trunking bracket (bracket arm) 1 | Trunking bracket (bracket arm) 1 | Piece | 5 | |||

| Accessory 9 | Trunking bracket (bracket arm) 2 | Trunking bracket (bracket arm) 2 | Piece | 15 | |||

| Accessory 10 | Angle steel column (bridge hanger)100×260×20mm | Angle steel column (bridge hanger)100×260×20mm | Piece | 8 | |||

| Accessory 11 | Vertical equal diameter right upward bend | Vertical equal diameter right upward bend | Piece | 2 |  | |||||||

| Accessory 12 | Vertical equal diameter left upward bend | Vertical equal diameter left upward bend | Piece | 2 |  | |||||||

| Accessory 13 | Vertical equal diameter right downward bend | Vertical equal diameter right downward bend | Piece | 2 |  | |||||||

| Accessory 14 | Vertical equal diameter left downward bend | Vertical equal diameter left downward bend | Piece | 2 |  | |||||||

| Accessory 15 | Upper vertical equal diameter tee | Upper vertical equal diameter tee | Piece | 2 |  | |||||||

| Accessory 16 | Connecting plate10×20×100mm | Connecting plate10×20×100mm | Piece | 40 |  | |||||||

| Accessory 17 | Vertical equal diameter direction change bend | Vertical equal diameter direction change bend | Piece | 4 | |||

| Accessory 18 | Connecting screw (special) | Connecting screw (special) | Set | 150 | M5×10 with 1 self-locking nut per set | ||

| Accessory 19 | Copper grounding screw (special) | Copper grounding screw (special) | Set | 80 | M5×15 with 1 nut and 2 flat washers per set | ||

| Accessory 20 | Cover plate mounting clip | Cover plate mounting clip | Piece | 100 | |||

| 24 | PVC straight through | PVC straight through | Φ16 | Φ16 | Piece | 2 | |

| Φ20 | Φ20 | Piece | 2 | ||||

| 25 | PVC elbow | PVC elbow | Φ16 | Φ16 | Piece | 2 | |

| Φ20 | Φ20 | Piece | 2 | ||||

| 26 | Porous plate plug | Porous plate plug | Piece | 20 | |||

| 27 | Tower-type rubber ring | Tower-type rubber ring | φ30 | φ30 | Piece | 4 | |

| 28 | Answer device bracket | Answer device bracket | Piece | 1 | |||

| 29 | Safety connecting wire | Safety connecting wire | 40 pieces/package | 40 pieces/package | Package | 1 | |

| 30 | Intelligent answer device | Intelligent answer device | Piece | 1 | |||

| 31 | U-type insulated terminal | U-type insulated terminal | SV2-5L black | SV2-5L black | Piece | 20 | For electrical box circuit breaker leads |

| 32 | O-type insulated terminal | O-type insulated terminal | RV 2-5 blue | RV 2-5 blue | Piece | 100 | For bridge grounding wire |

- Tools

| Serial Number | Name | Specification/Model | Unit | Quantity | Remarks (Description) |

| 1 | Long-nose pliers | 6 inches | Handle | 1 | |

| 2 | Wire stripper | Handle | 1 | ||

| 3 | Crimping pliers | HS-30J | Handle | 1 | Crimping cold-pressed terminals |

| 4 | Crimping pliers | HS-06WF | Handle | 1 | Crimping pins |

| 5 | Steel wire pliers | DL2006 | Handle | 1 | |

| 6 | Flat-blade screwdriver | 3 inches | Handle | 1 | |

| 7 | Cross screwdriver | 3 inches | Handle | 1 | |

| 8 | Flat-blade screwdriver | 2×75 | Handle | 1 | |

| 9 | Cross screwdriver | 2×75 | Handle | 1 | |

| 10 | Test pencil | Handle | 1 | ||

| 11 | Digital multimeter | MY60 | Piece | 1 | |

| 12 | Aluminum alloy stepladder | 1.5 meters | Pair | 1 | |

| 13 | File | 8 inches | Root | 1 | |

| 14 | Steel tape measure | 3m | Piece | 1 | |

| 15 | Electrician’s knife | Handle | 1 | ||

| 16 | Steel square | 300mm | Handle | 1 | |

| 17 | Steel ruler | 300mm | Handle | 1 | |

| 18 | Adjustable wrench | 6 inches | Handle | 1 | |

| 19 | Hexagon wrench | BS-C7 | Set | 1 | 7-piece set |

| 20 | Hacksaw frame | 10 inches, adjustable | Frame | 1 | |

| 21 | Hacksaw blade | Matching | Strip | 3 | |

| 22 | Spring pipe bender | Φ16 | Root | 1 | |

| 23 | Spring pipe bender | Φ20 | Root | 1 | |

| 24 | Power strip | Piece | 2 | ||

| 25 | Safety sign | 160×200mm | Sheet | 1 | Must wear safety helmet |

| 26 | Safety sign | 160×200mm | Sheet | 1 | Danger high voltage keep out |

| 27 | Safety sign | 160×200mm | Sheet | 1 | Beware of falling objects |

| 28 | Safety sign | 160×200mm | Sheet | 1 | Do not close the switch, people are working |

| 29 | Safety sign | 160×200mm | Sheet | 1 | Beware of electric shock |

| 30 | Electrical Installation and Maintenance Training and Assessment Device Training Guide | Book | 1 |

Others

| Serial Number | Name | Specification/Model | Unit | Quantity | Remarks (Description) | Remarks (Description) | Remarks (Description) | Status |

| 1 | BOH-G101 Electrical Installation and Maintenance Training and Assessment Device Stand (2-person group standard configuration) | Length × width × height =2006mm × 1003mm × 2410mm | Group | 1 | See drawings | Material name | Unit/Quantity | Shipped in bulkAssembled on site |

| Adopting industrial aluminum profile frame structure, equipped with mesh panels, 外包彩色钢制门框 | ||||||||

| 2 | Component storage cabinet | Piece | 1 | Shipped in bulk | ||||

| 3 | Mobile tool table | Vehicle | 1 | With heavy-duty self-locking casters | With heavy-duty self-locking casters | With heavy-duty self-locking casters | Same as above | |

| 4 | Electric heater (electric heat source) | Piece | 1 | Same as above | ||||

| 5 | Distribution box | PZ30-12 surface-mounted type | Piece | 1 | ||||

| 6 | Residual current air switch | DZ47LE-32/C6 | Piece | 2 | 1P+N | 1P+N | 1P+N | Same as above |

| 7 | Air switch | DZ47-63/C6 | Piece | 2 | 1P | 1P | 1P | Same as above |

| 8 | Machine tool hanging plate | CA6140 lathe circuit wireless assessment hanging box | Set | 1 | Equipped with wireless liquid crystal assessment answer device and teacher assessment software | Equipped with wireless liquid crystal assessment answer device and teacher assessment software | Equipped with wireless liquid crystal assessment answer device and teacher assessment software | Same as above |

| M7120 grinder circuit wireless assessment hanging box | Set | 1 | ||||||

| X62W universal milling machine circuit wireless assessment hanging box | Set | 1 | ||||||

| T68 boring machine circuit wireless assessment hanging box | Set | 1 | ||||||

| 9 | Machine tool hanging plate bracket | Special | Block | 1 | Same as above | |||

| 10 | Insulating carpet | ㎡ | 1 | Two pieces of 1m × 3m | Two pieces of 1m × 3m | Two pieces of 1m × 3m | Same as above |

Examples of Training Projects

- Installation of electricity meter box

- Installation of distribution box

- Installation of fluorescent lamp

- Installation of incandescent lamp

- Installation of ceiling lamp

- Installation of energy-saving lamp

- Installation of high-pressure sodium lamp

- Processing and arrangement of PVC pipe

- Threading of PVC pipe

- Installation of switches and sockets

- Installation of junction box

- Line distribution design

- Study and training of construction specifications

- Study and training of safe construction requirements

- Two-place control of one lamp

- Trunking wiring construction training

- Concealed works construction training

- Installation of isolating switch

- Wiring training of distribution lines

Combination and installation training of metal bridge;

Laying training of plastic trunking;

Laying training of metal conduit;

- Installation of electrical control box

- Electrical control circuit installation training

Connection of direct start and stop control circuit of three-phase asynchronous motor;

Connection of contactor interlocked forward and reverse control circuit of three-phase AC asynchronous motor;

Connection of button interlocked forward and reverse control circuit of three-phase AC asynchronous motor;

Connection of button and contactor composite interlocked forward and reverse control circuit of three-phase AC asynchronous motor;

Connection of Y-△ (manual switching) starting control circuit of three-phase AC asynchronous motor;

Connection of Y-△ (time relay switching) starting control circuit of three-phase AC asynchronous motor;

Connection of stator winding series resistance starting control circuit;

Connection of dynamic braking control circuit of three-phase AC asynchronous motor;

Connection of reverse connection braking control circuit of three-phase AC asynchronous motor;

Connection of sequence control circuit of multiple motors (3 or less);

Connection of motor’s round-trip travel control circuit;

Forward and reverse control of DC motor;

Speed regulation experiment of DC motor;

Connection of common lathe control circuit;

Connection of electric hoist control circuit;

Connection of control circuit for three-phase AC asynchronous motor to realize both inching and continuous rotation;

Connection of two-place control circuit;

Connection of double-speed motor speed regulation control circuit with button switching;

Connection of double-speed motor speed regulation control circuit with time relay switching;

Connection of reverse connection braking control circuit with centrifugal switch;

- Inverter panel function parameter setting and operation training;

- Inverter’s inching control, start-stop control of motor;

- Multi-stage control of motor speed;

- Power frequency and frequency conversion switching control;

- Motor open-loop speed regulation based on analog control;

- Motor open-loop speed regulation based on panel operation;

- Inverter protection and alarm function training;

- PLC-based inverter open-loop speed regulation;

- PLC-controlled motor sequence starting;

- PLC-controlled three-phase asynchronous motor Y-△ starting circuit;

- Parameter setting of touch screen;

- Programming of touch screen;

- Comprehensive training of touch screen, PLC and inverter;

- Control of two-phase hybrid stepper motor;

- Wireless assessment intelligent training of CA6140 lathe circuit

- Wireless assessment intelligent training of M7120 grinder circuit

- Wireless assessment intelligent training of X62W universal milling machine

- Wireless assessment intelligent training of T68 boring machine circuit

IV. Technical Parameters

Working power supply: Three-phase five-wire power supply AC 380 V/220 V ±7.5% 50 Hz;

Working environment: Using insulating floor (or using insulating carpet);

Size of main mesh panel of training device: Length (mm) × width (mm) = 798 × 768

Overall dimensions of training device: See configuration list

Material of training device: Steel plate. Thickness of steel plate

Maximum power consumption ≤1.5KW

Safety protection measures: With grounding protection, overcurrent, overload, leakage protection functions, in line with relevant national standards.