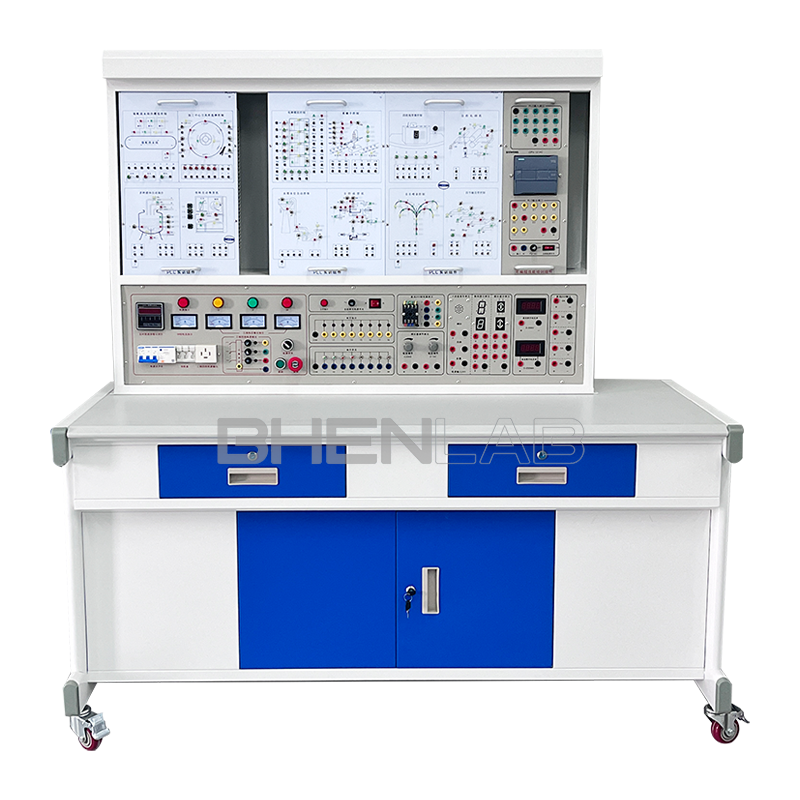

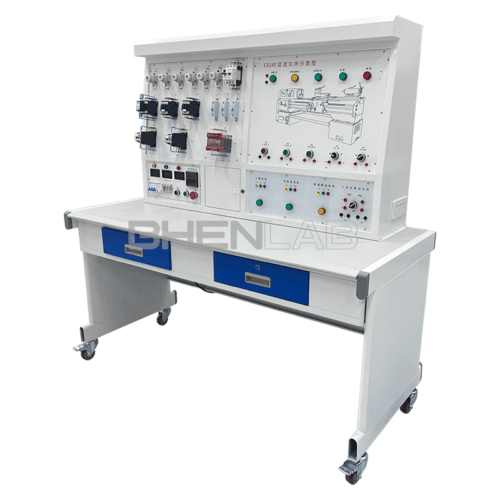

This electrical skills training and assessment experimental device for machine tools is developed for the teaching and assessment of electrical control content in colleges and universities, vocational schools (for electrical, automation and related majors), social electrician training, and county-level maintenance electrician appraisal institutes (stations). It can be used for classroom demonstrations, principle operations and experimental internships of machine tool electrical control. The device artificially and covertly sets dozens of circuit faults. With the help of principle analysis, students can receive comprehensive and real training in troubleshooting machine tool electrical faults. It is an ideal equipment for skill training and assessment, with remarkable teaching effects.

I. Basic Configuration of the Experimental Device

- AC power supply (with leakage protection measures): Provides three-phase AC power supply (380V).

- Personal safety protection system: A voltage-type leakage protection device is installed on the screen. If there is a leakage in the control screen or strong electricity output, the power supply will be cut off immediately to ensure the safety of the experiment process.

- Three-dimensional color diagram of the machine tool: The panel is printed with a color three-dimensional outline drawing of each machine tool, which can intuitively show the outline of various machine tools, with a realistic machine tool shape.

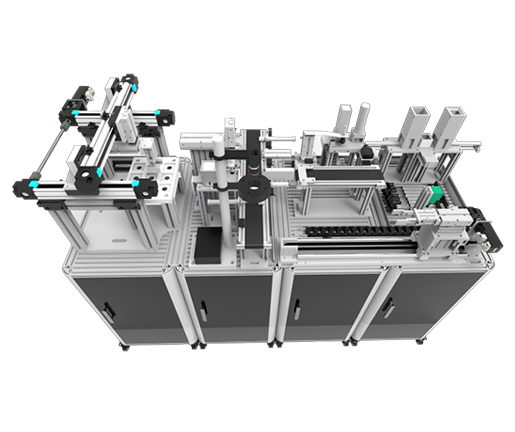

- Three-phase asynchronous motor: The experimental platform is equipped with 3 three-phase squirrel-cage asynchronous motors, which are used as spindle motor, feed motor, cooling pump motor, etc.

- Fault switch box: Equipped with 12 fault switches.

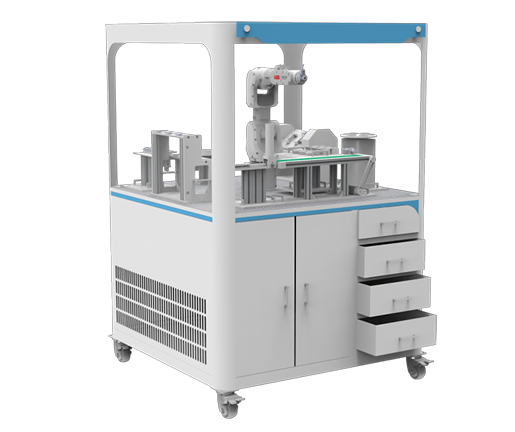

- Experimental desk: The experimental desk has a double-layer iron matte dense-grain spray structure, with a density board desktop. It has a solid structure, a cuboid-like shape, and an elegant appearance. It is equipped with two large drawers for placing tools and materials. The desktop is used to install the power control screen and provide a spacious work surface.

II. Experimental Projects and Main Contents:

- Students are familiar with the structure and principle of common low-voltage electrical appliances.

- In the electrical schematic mode, students find out that the fault point is on a certain line through measurement with the help of principle analysis.

- Improve students’ practical ability and skill operation level.

- Complete the troubleshooting of common machine tool faults through troubleshooting of machine tools.

- Fault points can be set as a skill assessment platform for maintenance electricians.

III. Technical Performance:

- Input power supply: Three-phase four-wire 380V AC power supply.

- Structure: The experimental platform has an iron sheet metal spray structure, which is firm and durable.

- Working environment: Temperature -10°C – +40°C.

- Total power consumption of the whole machine: <2KW.

List of Electrical Configuration of the Experimental Platform:

| Code | Component Name | Quantity | Purpose |

| M1 | Motor | 1 | Drive spindle |

| M2 | Motor | 1 | Drive cooling pump |

| M3 | Motor | 1 | Quick feed |

| QS1 | Switch | 1 | Main switch |

| QS2 | Switch | 1 | Lighting switch |

| SA | Switch | 1 | Control cooling pump motor |

| FU1 | Fuse | 1 | Main power supply fuse |

| FU2 | Fuse | 1 | Control circuit protection |

| FU3 | Fuse | 1 | Signal light short-circuit protection |

| FU4 | Fuse | 1 | Lighting short-circuit protection |

| FR1 | Thermal relay | 1 | M1 overload protection |

| FR2 | Thermal relay | 1 | M2 overload protection |

| T | Transformer | 1 | Rectification, circuit, lighting power supply |

| KM1 | Contactor | 1 | Spindle start |

| KM2 | Contactor | 1 | Control cooling pump |

| KM3 | Contactor | 1 | Control tool post quick motor |

| SB1 | Button | 1 | Stop button |

| SB2 | Button | 1 | Start button |

| SB3 | Button | 1 | Control quick motor start |

| HL | Signal light | 1 | Indicate power signal light |

| EL | Low-voltage lighting | 1 | Low-voltage lighting |

Fault Phenomena:

- Fault 1: Open circuit, all motors lack one phase.

- Fault 2: Open circuit, the spindle motor lacks two phases and cannot run.

- Fault 3: Open circuit, the cooling pump motor lacks two phases and cannot run.

- Fault 4: Open circuit, the tool post quick movement motor lacks two phases and cannot run.

- Fault 5: Open circuit, all control circuits fail.

- Fault 6: Open circuit, all control circuits fail.

- Fault 7: Open circuit, all control circuits fail.

- Fault 8: Open circuit, all control circuits fail.

- Fault 9: Open circuit, the spindle motor control circuit fails.

- Fault 10: Open circuit, both the tool post and cooling pump control circuits fail.

- Fault 11: Open circuit, the tool post control circuit fails.

Fault 12: Open circuit, the cooling pump control circuit fails.