I. Product Overview

This device is specially developed for refrigeration-related majors offered by vocational colleges. Based on the characteristics of air-conditioning and refrigerator maintenance technology in the refrigeration industry, it is designed for the electrical control of air conditioners and refrigerators as well as the installation and maintenance of refrigeration systems. It strengthens students’ comprehensive vocational abilities in pipeline installation, electrical wiring, working condition debugging, fault diagnosis and maintenance of air-conditioning and refrigerator systems. The device integrates technologies such as fluid mechanics, thermodynamics, heat transfer and electrical control, and is suitable for teaching and training in refrigeration-related majors.

II. Functional Features

1.The device can fully demonstrate the structure of the refrigeration system and the entire process of refrigeration system maintenance, meeting the needs of practical training teaching, actual engineering training and vocational skills competitions.

2.It has strong comprehensiveness, can form multiple refrigeration systems, has multiple control modes, and has strong practicability, versatility and economy.

3.The device adopts a modular design, with electrical control and refrigeration system separated independently. Relevant characteristic points can be measured, which not only ensures the training and consolidation of students’ basic skills, but also ensures the rapidity, safety and reliability of circuit connection.

4.It can simulate fault settings. Students can analyze the possible causes of faults according to the process, determine the scope of faults, and eliminate them. It is conducive to carrying out skill appraisal and assessment work.

5.Intelligent Training Assessment System

1.Technical Description of Wireless Intelligent Assessor

1.The assessor is formed by one-time molding of high-quality PVC mold, with a color PVC panel pasted on the surface. The left side of the assessor is connected to the assessment module and the incoming power supply. The external dimension is 263X183X96mm.

2.The assessment keys adopt digital touch buttons with clear hand feel and sensitive response.

3.The man-machine interface adopts a 3.2-inch blue light LCD display, which is simple and clear to operate and has good interactivity.

4.Data transmission adopts high-quality wireless network modules to ensure the distance and accuracy of data transmission.

5.The circuit design is optimized and reasonable, and the production process is strict and perfect, ensuring the reliability and stability of the machine.

6.It can set up to 60 fault points (after expansion).

7.Fault numbers can be changed at will.

8.Each fault point can be set as an open or short-circuit fault.

9.The set parameters will not be lost after power failure.

10.The contact capacity of the output relay reaches 5A/AC250V, which can be used for both strong electricity and weak electricity.

11.It adopts an independent switching power supply for power supply, with a wide input voltage range, small size, light weight and high efficiency.

2.Functional Description of the Assessment System

1.a.It has functions such as automatic scoring parameter setting, assessment time setting and countdown, and duplicate test number alarm.

2.a.It can choose the specified fault assessment mode or random fault assessment mode.

3.a.In the random fault assessment mode, the system has an automatic question-setting function, so that each fault is different.

4.a.The random fault assessment mode can set the fault range and the number of faults.

5.a.It can automatically save the test number, score, number of wrong eliminations, remaining faults, remaining time, etc. of 80 candidates.

6.a.The set faults and assessment results will not be lost after power failure.

III. Technical Performance

- Input power supply: Single-phase three-wire 220V±10% 50Hz

- Device capacity: ≤1.5kVA

- Overall dimensions: Not less than 1500mm×800mm×1400mm

- Air-conditioning system compressor: Input power not less than 585W

- Refrigerator system compressor: Input power not less than 65W

- Refrigerant type: Air-conditioning system R22, refrigerator system R600a

- Safety protection: Equipped with leakage voltage and leakage current protection, meeting national safety standards

IV. System Composition and Functions

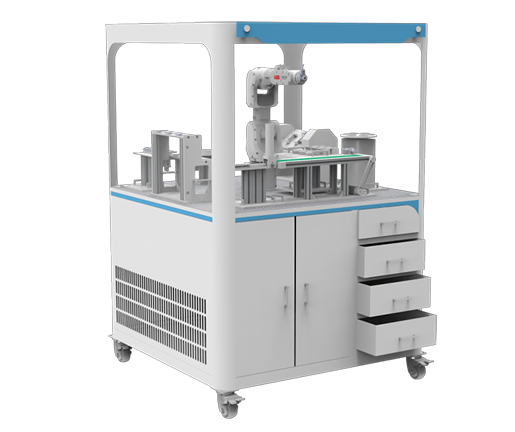

- The device adopts a modular design and is composed of a guide rail-type aluminum alloy installation platform, an air-conditioning system, a refrigerator system, an electrical control system, etc.

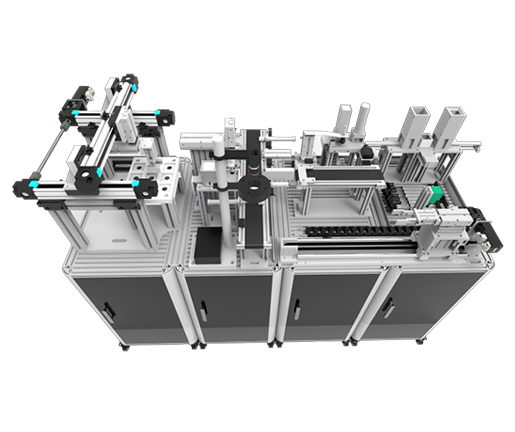

- The guide rail-type aluminum alloy installation platform is composed of standard aluminum alloy industrial profiles, serving as a platform for students’ operation training, on which air-conditioning system components and refrigerator system components are installed.

- Air-conditioning system: Including air-conditioning compressor, indoor heat exchanger, outdoor heat exchanger, four-way reversing valve, throttling device, liquid sight glass, air-conditioning valve, etc.

- Refrigerator system: Including refrigerator compressor, wire condenser, freezer evaporator, refrigerator evaporator, throttling device, liquid sight glass, solenoid valve, drying filter, etc.

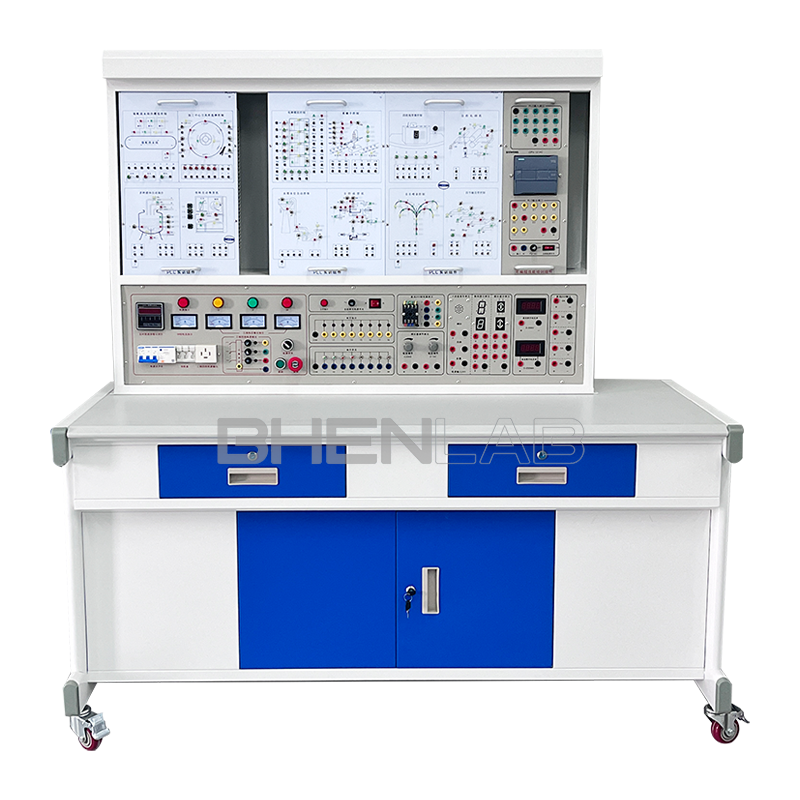

- Electrical control system: Adopting a modular design, it has 5 hanging box modules, including power supply and instrument module, air-conditioning electrical training assessment module, refrigerator electronic temperature control training assessment module, refrigerator intelligent temperature control electrical training assessment module, and intelligent assessment module.

- Power supply and instrument module:

Supplied by single-phase three-wire 220V AC power. 1 AC voltmeter with a measurement range of 0~250V; 1 AC ammeter with a measurement range of 0~5A, used to measure the system starting current and monitor the normal working current of the system. - Refrigeration system pressure detection unit:

Provided with 4 vacuum pressure gauges with measurement ranges of -0.1~9MPa, -0.1~1.5MPa, -0.1~3.5MPa respectively, used to measure the high and low pressure side pressures of air-conditioning and refrigerator systems. - 1 set of current-type leakage protection device

When the leakage current exceeds a certain value, it trips to cut off the power supply; thermal protection devices are provided to protect the compressor from overheating and overload.

V. System Basic Configuration Table

| Número de serie | Nombre del equipo | Main Functions of Equipment (Technical Parameters and Requirements) | Quantity (set/unit) | Remarks |

| 1 | Training Platform | Specification: 1500mm×800mm×1350mm. The cross-sectional dimension of 4 column aluminum profiles: 30mm30mm. The cross-sectional dimension of aluminum profiles on the tabletop: 20mm80mm. The tabletop is assembled with profiles, and the thickness of the inlaid plate: 9mm; with movable drawers and movable unit cabinets | 1 | |

| 2 | Air-Conditioning System Module | With transparent visible organic glass panel, provided with test pin holes for circuit detection. Including rotary compressor, indoor heat exchanger, outdoor heat exchanger, four-way reversing valve, throttling device, liquid sight glass, air-conditioning valve, etc. | 1 | |

| 3 | Refrigerator System Module | With transparent visible organic glass panel, provided with test pin holes for circuit detection. Including piston compressor, wire condenser, freezer evaporator, refrigerator evaporator, throttling device, liquid sight glass, solenoid valve, drying filter, etc. | 1 | |

| 4 | Power Supply and Instrument Module | AC220V power supply, AC voltmeter 0~250V, AC ammeter 0~5A | 1 | |

| Air-Conditioning Electrical Training Assessment Module | With transparent visible organic glass panel, provided with test pin holes for circuit detection. Air-conditioning universal control module with cooling, heating, ventilation and dehumidification control functions; the panel is divided into circuit principle test part, strong electricity interface part and intelligent assessment interface. | 1 | ||

| 5 | Refrigerator Electronic Temperature Control Electrical Training Assessment Module | With transparent visible organic glass panel, provided with test pin holes for circuit detection. Toshiba GR-204E electronic temperature control module, which can control direct-cooling double-door refrigerators; the panel is divided into circuit principle test part, strong electricity interface part and intelligent assessment interface. | 1 | |

| 6 | Refrigerator Intelligent Temperature Control Electrical Training Assessment Module | With transparent visible organic glass panel, provided with test pin holes for circuit detection. Single-chip microcomputer control, liquid crystal display, double temperature control; with quick freezing function and intelligent temperature control; the panel is divided into circuit principle test part, strong electricity interface part and intelligent assessment interface. | 1 | |

| 7 | Intelligent Assessment Module | Wireless WIFI intelligent assessment system, equipped with dot-matrix blue backlight liquid crystal display and PVC touch keyboard. | 1 | |

| 8 | Power Box | Provides AC 14.5V power supply and DC 5V/1A power supply | 1 | |

| 9 | Refrigeration Special Tools | 1. Portable welding tool: 1 set 2. Rotary vane vacuum pump: 1 set 3. Pipe expanding tool: 1 set 4. Eccentric pipe expander: 1 set (including chamfering tool and cutter) 5. Pipe bender: 1 piece 6. Dual-meter repair valve: 1 piece 7. Three-color liquid filling pipe: 100cm, 3 pieces 8. Male/female adapter for dual-meter repair valve: 3 pieces 9. 3Kg refrigerant cylinder: 1 piece |

1 | |

| 10 | Other Tools and Accessories Configuration | 1. Hexagon socket wrench: 2 pieces (4mm and 5mm each) 2. 250mm adjustable wrench: 2 pieces 3. Long-handled screwdriver: 1 piece 4. Tape measure: 1 piece (3m) 5. Wire hanging rack: 1 set 6. Water receiving tray: 1 piece 7. Wire: 1 set (45 pieces/set) 8. Bottle opener: 1 piece (special for R600a refrigerant bottle) 9. User manual: 1 copy 10. Intelligent assessment system software: 1 disc 11. Intelligent answerer user manual: 1 copy |

1 |

VI. Training Projects

1. Air-Conditioning System Pipeline Design, Assembly, Wiring and Debugging Projects

- Pipeline Design Task

Design of air-conditioning system pipelines (including determination of pipeline distance, pipe cutting, pipe bending, pipe expanding, pipe flaring, pipeline welding, etc.) - System Assembly Task

Install the designed pipelines to the reasonable positions of corresponding components and complete the pressure maintaining and leak detection of the air-conditioning system. - System Wiring Task

Judge the windings of the air-conditioning compressor, and complete the pipeline laying and connection of the air-conditioning system. - System Debugging Task

Complete the vacuum pumping, refrigerant charging, electrical debugging and working condition adjustment of the air-conditioning system. - System Electrical Assessment Task

Complete the fault setting, measurement, troubleshooting, debugging and operation of air-conditioning electrical appliances. - Air-Conditioning Electrical Training Assessment Module (Fault Settings)

K1: Simulate open circuit on the secondary side of transformer T1

K2: Simulate open circuit of integrated voltage regulator 7805

K3: Simulate emergency switch failure

K4: Simulate open circuit of ambient temperature sensor

K5: Simulate open circuit of tube temperature sensor

K6: Simulate open circuit fault of resistor R1

K7: Simulate open circuit fault of resistor R2

K8: Simulate open circuit fault of resistor R6

K9: Simulate open circuit fault of resistor R7

K10: Simulate open circuit fault of resistor R8

K11: Simulate open circuit fault of resistor R9

K12: Simulate open circuit of relay K3 coil

K13: Simulate open circuit of relay K4 coil

K14: Simulate open circuit of relay K5 coil

K15: Simulate open circuit of relay K6 coil

K16: Simulate open circuit of relay K7 coil

K17: Simulate open circuit of relay K8 coil

K18: Simulate open circuit of indoor fan starting capacitor C3

K19: Simulate open circuit of outdoor fan starting capacitor C2

2. Refrigerator System Pipeline Design, Assembly, Wiring and Debugging Projects

- Pipeline Design Task

Design of refrigerator system pipelines (including determination of pipeline distance, pipe cutting, pipe bending, pipe expanding, pipe flaring, etc.) - System Assembly Task

Install the designed pipelines to the reasonable positions of corresponding components and complete the pressure maintaining and leak detection of the refrigerator system. - System Wiring Task

Judge the windings of the refrigerator compressor, and complete the pipeline laying and connection of the refrigerator system. - System Debugging Task

Complete the vacuum pumping, refrigerant charging, electrical debugging and working condition adjustment of the refrigerator system. - System Electrical Assessment Task

Complete the fault setting, measurement, troubleshooting, debugging and operation of air-conditioning electrical appliances. - Refrigerator Electronic Temperature Control Electrical Training Assessment Module (Fault Settings)

K1: Open circuit on the secondary side of transformer T1

K2: No output from voltage regulator 7812

K3: 6.8 voltage regulator tube breakdown and short circuit

K4: Open circuit of RT1 refrigerator compartment sensor

K5: C4 capacitor breakdown and short circuit

K6: Open circuit of RT2 freezer compartment temperature sensor

K7: Open circuit of R19 resistor

K8: Q1 drive triode failure (base open circuit)

K9: Q2 drive triode failure (base open circuit)

K10: Defrost stop

K11: Defrost start button short circuit

K12: Open circuit of RY01 relay coil

K13: Open circuit of RY02 relay coil

K14: Open circuit of RY01 relay normally open contact

K15: Open circuit of RY02 relay normally closed contact

K16: Open circuit of RY02 relay normally open contact - Refrigerator Intelligent Temperature Control Electrical Training Assessment Module (Fault Settings)

K1: Simulate open circuit of transformer secondary AC12V

K2: Simulate open circuit of D5~D8 diode rectifier bridge

K3: Simulate open circuit of transformer secondary AC12V

K4: Simulate open circuit of D1~D4 diode rectifier bridge

K5: Simulate open circuit of 7805 voltage regulator

K6: Simulate open circuit of T1 voltage regulator tube

K7: Simulate open circuit of refrigerating compartment sensor

K8: Simulate open circuit of menu button

K9: Simulate open circuit of freezing compartment sensor

K10: Simulate open circuit of time button

K11: Simulate open circuit of power supply V3

K12: Simulate open circuit of Q5 triode

K13: Simulate open circuit of Q1 triode

K14: Simulate open circuit of relay RY1 coil

K15: Simulate open circuit of Q6 triode

K16: Simulate open circuit of relay RY3 coil

K17: Simulate open circuit of Q2 triode

K18: Simulate open circuit of relay RY2 coil

K19: Simulate open circuit of confirm button

K20: Simulate open circuit of setting button