I. Overview

The senior technician skills training and assessment equipment needs to be applicable to the electrical control circuits required by the textbooks Junior Maintenance Electrician, Intermediate Maintenance Electrician, and Senior Maintenance Electrician. Through training with the PLC programmable controller, frequency converter, and corresponding training modules equipped with the device, learners can quickly master the practical application technologies and operational skills required by the courses. It is targeted, practical, scientific, and advanced, meeting the requirements of the assessment outline for intermediate and senior maintenance electricians. It is an ideal equipment for vocational skill appraisal departments, colleges and universities, and technical schools to assess the skills of intermediate and senior maintenance electricians.

II. Technical Parameters

(1) Input voltage: Three-phase four-wire (or three-phase five-wire) ~380V±10% 50Hz

(2) Working environment: Temperature -10℃~+40℃; Relative humidity <85% (at 25℃); Altitude <4000m

(3) Device capacity: <1.5KVA

(4) Weight: Not less than 100Kg. Load-bearing capacity: Not more than 3000N/㎡.

(5) Overall dimensions: Not less than 1700×700×1630mm³.

(6) Leakage protection action current: ≤30mA; Leakage protection action time: ≤0.1s.

III. Configuration and Functions

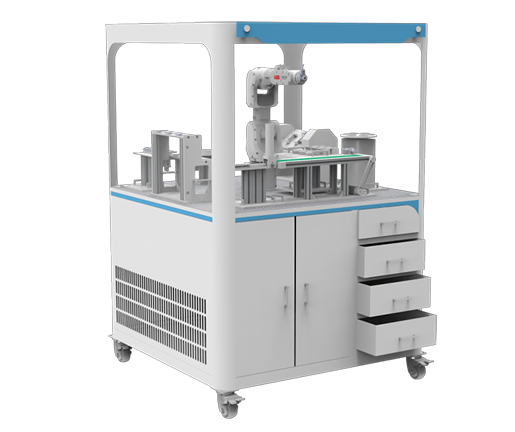

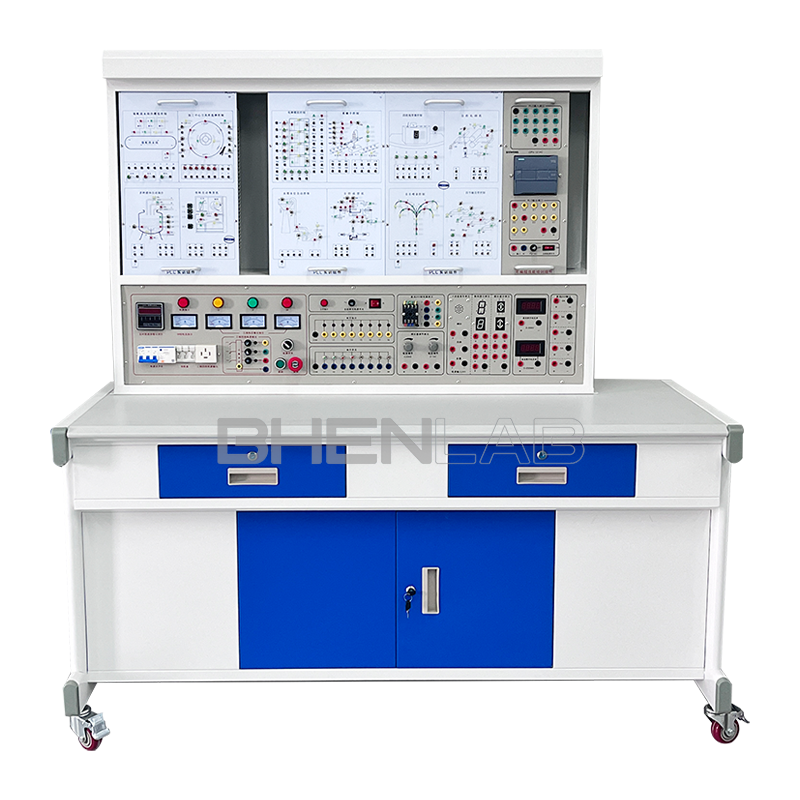

(1) The main control panel of the DW02 power control box is of a double-layer iron structure with matte dense texture spray coating, and the panel is made of aluminum.

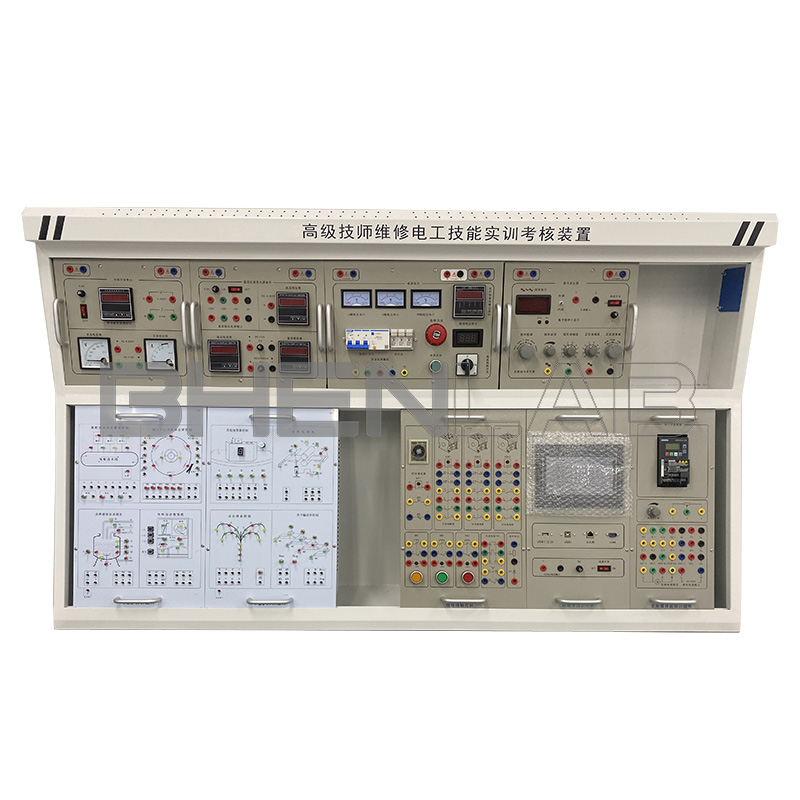

(2) Three-phase four-wire power input, after passing through a leakage protector and a main switch, controls the on/off of the contactor through start/stop buttons, and is equipped with an emergency stop control button.

(3) The control panel is equipped with a 450V pointer-type AC voltmeter, which can observe the three-phase grid voltage through a band switch.

(4) Timer and alarm recorder (service manager), which is usually used as a clock, with functions such as setting time, timing alarm, and power cutoff; it can also automatically record the total number of leakage alarms and power short circuits caused by wrong wiring or operations, providing a unified standard for assessing students’ practical skills.

(5) AC circuit measuring meter: 8-digit LED display, which can simultaneously measure current I, voltage V, power KW, electric energy KWh, and working time T in the working circuit. Accuracy: Class 1.0.

(6) AC low-voltage power supply: Equipped with an autotransformer with primary side 220V, secondary side 26V and 6.3V AC voltage. 6.3V is used for the signal indicator power supply, and 26V is used for the AC power supply of the rectifier circuit in energy-consuming braking.

(7) 4 pieces of 5408 diodes, used for the rectifier circuit of energy-consuming braking.

(8) Three 75Ω/75W resistors for motor step-down startup, and one 10Ω/25W resistor for asynchronous motor energy-consuming braking.

(9) Siemens CPU1214C PLC host, integrated with digital I/O (14 digital inputs / 10 digital outputs).

(10) Frequency conversion device (Siemens V20-0.4KW), powered by AC 220V, with a frequency control range of 0.2~400Hz, built-in EMC filter, output power 0.37kW. It integrates an RS485 communication interface and works in PWM mode (with vector control, sensorless vector speed/torque control) and other working modes; input and output points are all led to the module panel, and connected to the controlled object through plug-in wires; it adopts a modular design, facilitating expansion and combination; it can be used independently or in conjunction with PLC and electrical practical operation unit boards.

(11) Touch screen training component (physical object): 7-inch STN 256-color: Understand the functions and usage methods of industrial touch screens, master communication knowledge with PLC, and master the implementation methods of function keys such as reset, set, and toggle, graphic (curve) display, and dynamic screen tracking in the touch screen.

(12) The training desk is of a double-layer iron structure with matte dense texture spray coating, and the desktop is a fireproof, waterproof, and wear-resistant high-density board. The structure is firm, and the appearance is beautiful and elegant. The desk is equipped with two drawers (with locks) on each side and a cabinet, which can respectively place hanging parts and training items.

IV. Overall Configuration Table 1 of Maintenance Electrician Technician and Senior Technician Skills Training and Assessment Device

| Serial Number | Name | Unit | Quantity | Remarks | Remarks |

|---|---|---|---|---|---|

| 1 | Maintenance electrician training and assessment bench | Set | 1 | Overall dimensions: 1700mm×700mm×1650mm; Material: Steel-wood structure; Meets relevant national environmental protection requirements; Input voltage: AC 380V±10% 50Hz three-phase five-wire; Capacity: <1.5kVA; Experiment panel: Used for hanging training unit boards | Overall dimensions: 1700mm×700mm×1650mm; Material: Steel-wood structure; Meets relevant national environmental protection requirements; Input voltage: AC 380V±10% 50Hz three-phase five-wire; Capacity: <1.5kVA; Experiment panel: Used for hanging training unit boards |

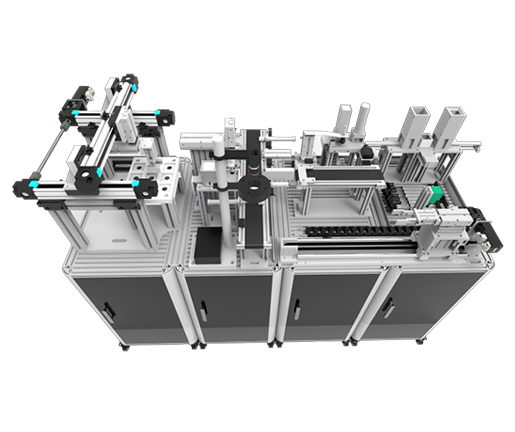

| 2 | Electrical control training unit hanging box and motor | Block | 1 | DW-05 | Electrical skills training component (V) |

| Block | 1 | DW-06 | Maintenance electrician training component (I) | ||

| Block | 1 | DW-07 | Maintenance electrician training component (II) | ||

| Block | 1 | DW-08 | Maintenance electrician training component (III) | ||

| Block | 1 | DW-09 | Maintenance electrician training component (IV) | ||

| Set | 1 | HLDJ-01 | Single-phase capacitor-start motor, AC 220V | ||

| HLDJ02 | Three-phase squirrel-cage motor AC 220V (Y) | ||||

| HLDJ03 | Three-phase squirrel-cage motor AC 380V (Y/△, with speed relay) | ||||

| HLDJ04 | Two-speed asynchronous motor AC 380V (△/YY) | ||||

| 3 | Instrument and lighting training hanging box | Set | 1 | See Table 3 | See Table 3 |

| 4 | Frequency converter training hanging box | Set | 1 | (Siemens) V20-0.4KW frequency converter, with communication interface and BOP operation panel. | (Siemens) V20-0.4KW frequency converter, with communication interface and BOP operation panel. |

| 5 | PLC host hanging box | Set | 1 | Siemens CPU1214c PLC host, integrated with digital I/O (14 digital inputs / 10 digital outputs) | Siemens CPU1214c PLC host, integrated with digital I/O (14 digital inputs / 10 digital outputs) |

| 6 | PLC training hanging box | Block | 1 | Answer device / musical fountain / assembly line / traffic lights / automatic water supply / Tian Ta Zhi Guang (Light of Tianjin Tower) | Answer device / musical fountain / assembly line / traffic lights / automatic water supply / Tian Ta Zhi Guang (Light of Tianjin Tower) |

| Automatic feeding and loading / four-section conveyor belt / multi-liquid mixing device / automatic vending machine / automatic rolling mill / mail sorter | Automatic feeding and loading / four-section conveyor belt / multi-liquid mixing device / automatic vending machine / automatic rolling mill / mail sorter | ||||

| Manipulator control / automatic forming machine / machining center | Manipulator control / automatic forming machine / machining center | ||||

| Four-story elevator / basic experiment / intermediate relay | Four-story elevator / basic experiment / intermediate relay | ||||

| 7 | Motor guide rail and optical code disc speed measurement system | Set | 1 | Including one set of optical code disc speed measurement system (equipped with imported photoelectric encoder), one stainless steel guide rail, with good flatness, no stress deformation, and good concentricity | Including one set of optical code disc speed measurement system (equipped with imported photoelectric encoder), one stainless steel guide rail, with good flatness, no stress deformation, and good concentricity |

| 8 | Touch screen training component (physical object) | Set | 1 | Kunlun Tongtai, 7-inch STN 256-color | Kunlun Tongtai, 7-inch STN 256-color |

| 9 | PLC simulation training software | Set | 1 | (1) Real-time display of PLC operation status through PLASH virtual environment (2) PLC programming training, PLC program writing and testing functions (3) Realization of PLC operation simulation and error program checking | (1) Real-time display of PLC operation status through PLASH virtual environment (2) PLC programming training, PLC program writing and testing functions (3) Realization of PLC operation simulation and error program checking |

| 10 | Maintenance electrician power drag simulation software | Set | 1 | 3D modeling is intuitive, which can meet the needs of students for multimedia teaching of electrical component structure, function, installation, wiring, circuit analysis, and virtual wiring training and knowledge assessment test functions for familiarizing with electrical control circuits. | 3D modeling is intuitive, which can meet the needs of students for multimedia teaching of electrical component structure, function, installation, wiring, circuit analysis, and virtual wiring training and knowledge assessment test functions for familiarizing with electrical control circuits. |

| 11 | Electrical connecting wires | Set | 1 | 20 pieces: 1000mm long – 6 yellow, 6 green, 6 red, 2 black; 10 pieces: 600mm long – 2 yellow, 2 green, 2 red, 2 blue, 2 black. | 20 pieces: 1000mm long – 6 yellow, 6 green, 6 red, 2 black; 10 pieces: 600mm long – 2 yellow, 2 green, 2 red, 2 blue, 2 black. |

| 12 | Common tools | Set | 1 | 1 flat-blade screwdriver; 1 cross screwdriver; 1 wire stripper; 1 pointer multimeter; 1 diagonal pliers. | 1 flat-blade screwdriver; 1 cross screwdriver; 1 wire stripper; 1 pointer multimeter; 1 diagonal pliers. |

| 13 | Experiment instruction manual | Set | 1 | Guide students’ training | Guide students’ training |

Table 2: Configuration Description Table of Electrical Control Training and Assessment Hanging Boxes for Maintenance Electrician Technician and Senior Technician Skills Training and Assessment Device

| Serial Number | Name | Unit | Quantity | Remarks |

|---|---|---|---|---|

| 1 | DW-05 Electrical skills training component | Provides two groups of 90Ω×2/1.3A disk resistors; one group of 900Ω×2/0.41A disk resistors. | ||

| 2 | DW-06 Maintenance electrician training component (I) | Set | 1 | Provides 2 capacitors, 1 AC solenoid valve, 1 AC contactor, 3 thermal relays |

| 3 | DW-07 Maintenance electrician training component (II) | Piece | 1 | Provides 1 air switch, 2 3P fuses, 3 AC contactors. |

| 4 | DW-08 Maintenance electrician training component (III) | Piece | 1 | Provides 2 power-on delay time relays, 1 power-off delay time relay, 4 travel switches, 6 buttons of various colors |

| 5 | DW-09 Maintenance electrician training component (IV) | Provides 4 AC contactors |

Table 3: Configuration Description Table of Instrument and Lighting Training Hanging Boxes for Maintenance Electrician Technician and Senior Technician Skills Training and Assessment Device

| Serial Number | Hanging Box Number | Training Module Name | Quantity | Remarks |

|---|---|---|---|---|

| 1 | DW-10 | Instrument and lighting training and assessment component (I) | 1 piece | Provides 1 two-pole leakage protector, 2 3P fuses, 1 knife switch, 1 single-phase watt-hour meter |

| 2 | DW-11 | Instrument and lighting training and assessment component (II) | 1 piece | Provides 2 screw lamp holders, 3 switch boxes, 1 ballast, 1 starter, 1 fluorescent lamp, 2 toggle switches, 1 double switch |

| 3 | DW-12 | Instrument and lighting training and assessment component (III) | 1 piece | Provides 3 AC ammeters, 3 current transformers |

| 4 | DW-13 | Instrument and lighting training and assessment component (IV) | 1 piece | Provides 1 AC voltmeter, 1 voltage indicator switch |

| 5 | DW-14 | Instrument and lighting training and assessment component (V) | 1 piece | Provides 1 three-phase three-wire active watt-hour meter |

| 6 | DW-15 | Instrument and lighting training and assessment component (VI) | 1 piece | Provides 1 three-phase four-wire active watt-hour meter |

| 7 | DW-16 | Instrument and lighting training and assessment component (VII) | 1 piece | Provides 1 three-phase four-wire reactive watt-hour meter |

V. Training Projects

-

Direct start control circuit of three-phase asynchronous motor

-

Inching control circuit of three-phase asynchronous motor

-

Self-locking control circuit of three-phase asynchronous motor

-

Button interlock forward and reverse control circuit of three-phase asynchronous motor

-

Contactor interlock forward and reverse control circuit of three-phase asynchronous motor

-

Double interlock forward and reverse control circuit of three-phase asynchronous motor

-

Automatic reciprocating control circuit of three-phase asynchronous motor workbench

-

Sequential start and stop control circuit of two three-phase asynchronous motors

-

Two-place control circuit of three-phase asynchronous motor

-

Y-△ control by contactor

-

Y-△ control by time relay

-

Single-direction start reverse connection braking control circuit of three-phase asynchronous motor

-

Single-direction start energy-consuming braking control circuit of three-phase asynchronous motor with transformerless half-wave rectification

-

Single-direction start energy-consuming braking control circuit of three-phase asynchronous motor with transformer full-wave rectification

-

Forward and reverse start energy-consuming braking control circuit of three-phase asynchronous motor

-

Capacitor start control circuit of single-phase squirrel-cage motor

-

Manual speed change control circuit of two-speed AC asynchronous motor

-

Automatic speed change control circuit of two-speed AC asynchronous motor

-

Y-△ start control circuit with power-off delay DC energy-consuming braking

-

Forward and reverse energy-consuming braking control circuit of three-phase asynchronous motor

-

Forward and reverse start reverse connection braking control circuit of three-phase asynchronous motor

-

Electrical control circuit of C620 lathe

-

Electrical control of electric hoist

-

Control circuit of Y3150 gear hobbing machine

-

Basic instruction operation of programmable controller

-

LED digital display control

-

Simulation of Tian Ta Zhi Guang (Light of Tianjin Tower) control

-

Simulation of crossroads traffic lights

-

Simulation of manipulator actions

-

Simulation of four-section conveyor belt

-

Simulation of assembly line control

-

Simulation of five-phase stepping motor control

-

Simulation of water tower water level control

-

Simulation of liquid mixing device control

-

Simulation of mail sorter control

-

Simulation of rolling mill control

-

Simulation of automatic forming machine control

-

Simulation of automatic feeding and loading control

-

Simulation of fully automatic washing machine control

-

Simulation of electroplating production line control

-

PLC-controlled forward and reverse control of three-phase asynchronous motor

-

PLC-controlled Y-△ start control of three-phase asynchronous motor

-

PLC-controlled step-down start control of three-phase asynchronous motor

-

PLC-controlled energy-consuming braking control of three-phase asynchronous motor

-

Parameter setting and operation of frequency converter functions

-

Alarm and protection functions of frequency converter

-

Multi-speed selection variable frequency speed regulation

-

External terminal inching control

-

Control of motor forward and reverse movement

-

Control of motor running time operation

-

Parameter setting of frequency converter for momentary power failure

-

External voltage variable frequency speed regulation

-

External current variable frequency speed regulation

-

Open-loop speed regulation of three-phase asynchronous motor by frequency converter

-

PLC-controlled frequency converter speed regulation

-

Basic instruction programming practice based on touch screen control mode

-

PLC-controlled LED control based on touch screen control mode

-

PLC-controlled manipulator control based on touch screen control mode

-

Communication control among PLC, touch screen, and frequency converter

-

485 bus network communication technology based on MCGS

-

Socket and one switch controlling one lamp (incandescent lamp, fluorescent lamp + two-pole leakage switch)

-

Two double switches controlling one lamp (incandescent lamp, fluorescent lamp + two-pole leakage switch)

-

Three switches controlling one lamp (incandescent lamp, fluorescent lamp + two-pole leakage switch)

-

Wiring of fluorescent lamp circuit

-

Wiring of sound-controlled switch controlling incandescent lamp circuit

-

Wiring of touch delay switch controlling incandescent lamp circuit

-

Wiring of human body induction switch controlling incandescent lamp circuit

-

Direct wiring circuit of single-phase watt-hour meter

-

Wiring circuit of single-phase watt-hour meter through current transformer

-

Wiring circuit of voltmeter and ammeter

-

Voltage measurement wiring of voltmeter with universal changeover switch for three-phase voltage

-

Control circuit wiring of single current transformer for single-phase circuit

-

Star connection circuit of three current transformers

-

Delta connection circuit of three current transformers

-

Measurement circuit of three-phase power factor meter

-

Wiring circuit of three-phase three-wire active watt-hour meter

-

Wiring circuit of three-phase three-wire active watt-hour meter through current transformer

-

Wiring circuit of three-phase four-wire active watt-hour meter

-

Wiring circuit of three-phase four-wire reactive watt-hour meter through current transformer

-

Wiring circuit of three-phase four-wire reactive watt-hour meter

-

Wiring circuit of three-phase four-wire reactive watt-hour meter through current transformer

-

Step-down start control circuit of motor with series autotransforme

BOH-01B Maintenance Electrician Technician and Senior Technician Skills Training and Assessment Device

Tags: Electrical Engineering Teaching EquipmentElectrical maintenance equipmentCategory: electricistaSKU: N/A

Brand: BHENLAB