I. Overview

The “BOH-G203 Advanced Maintenance Electrician and Skills Training and Assessment Training Device” is developed and produced in accordance with the “Mechanical Workers’ Vocational Skills Training Textbook” compiled by the Vocational Skills Appraisal and Guidance Center of the Machinery Industry. It allows for practical operations on electrical control circuits and practical electronic circuits listed in the textbooks “Elementary Maintenance Electrician Technology”, “Intermediate Maintenance Electrician Technology”, and “Advanced Maintenance Electrician Technology”, enabling quick mastery of the practical technologies and operational skills of the courses. It is targeted, practical, scientific, and advanced. This training device is not only suitable for students’ learning and practice but also an ideal equipment for skill assessment of elementary, intermediate, and advanced maintenance electricians in labor appraisal departments, colleges and universities, vocational schools, and technical schools.

II. Features

- The electrical components for electrical control circuit or electronic circuit experiments are all mounted on mounting plates as hanging boards, which are easy to operate and replace, allowing for function expansion or new experiment development; the selection of operation contents is typical and practical.

- The operation platform can be put into use only with a three-phase four-wire AC power supply, covering a small area, saving room usage, and reducing infrastructure investment.

- The control circuits for skill training and supporting small motors are specially designed to simulate various motor power drag systems in factories, and can meet the skill training requirements of maintenance electricians in installation, commissioning, fault analysis, and troubleshooting.

- It is equipped with voltage-type leakage protectors and current-type leakage protectors to ensure the safety of operators; each power output has monitoring and short-circuit protection functions, and each measuring instrument has reliable protection functions, making it safe and reliable to use; the control panel is also equipped with a timer and alarm recorder (service manager), providing a unified standard for the assessment of students’ experimental skills.

III. Technical Performance

- Input voltage: three-phase four-wire 380V±10% 50Hz

- Working environment: ambient temperature range -5~+40℃, relative humidity <85% (25℃), altitude <4000m

- Device capacity: <1.5KVA

- Overall dimensions: 170×70×150cm³

IV. Experimental Projects

(I) Electrical Control and Motor Drag Training

| 1. Direct start control of three-phase asynchronous motor 2. Contactor inching control circuit of three-phase asynchronous motor 3. Contactor self-locking control circuit of three-phase asynchronous motor 4. Manual control circuit for stator series resistance reduced-voltage starting of three-phase asynchronous motor 5. Automatic control circuit for stator series resistance reduced-voltage starting of three-phase asynchronous motor 6. Y-△ starting automatic control circuit 7. Forward and reverse control of three-phase asynchronous motor with reversing switch 8. Contactor interlocking forward and reverse control circuit 9. Button interlocking contactor forward and reverse control circuit of three-phase asynchronous motor 10. Double interlocking forward and reverse control circuit of three-phase asynchronous motor 11. One-way reduced-voltage starting and reverse connection braking control circuit 12. Energy consumption braking control circuit 13. Sequential control of three-phase asynchronous motor 14. Multi-location control of three-phase asynchronous motor |

15. Automatic reciprocating control circuit of workbench 16. Manual control circuit of three-phase wound-rotor asynchronous motor 17. Automatic starting control circuit of three-phase wound-rotor asynchronous motor 18. Wiring, fault and maintenance of C620 lathe 19. Electrical control circuit of Z3040 radial drilling machine 20. Control circuit of electric hoist 21. Contactor-controlled two-speed motor control circuit 22. Time relay-controlled two-speed motor control circuit 23. Starting control circuit with excitation added according to stator current principle 24. Simple synchronous motor energy consumption braking control circuit 25. DC motor starting and speed regulation 26. Series resistance starting and speed regulation in armature circuit of shunt-excited DC motor 27. Reverse control circuit with energy consumption braking 28. Field reverse connection braking control circuit |

|---|

(II) Comprehensive Training of Electrical and Electronic Technology

| 1. Fluorescent lamp wiring 2. Assembly of single-phase rectifier circuit 3. Assembly of parallel silicon voltage regulator tube voltage stabilizing circuit 4. Assembly of series transistor voltage stabilizing circuit 5. JS20 unijunction transistor time relay 6. JSJ transistor time relay |

7. Proximity switch 8. Testing of microphonic amplifier circuit 9. Quiz buzzer for intellectual competitions 10. Simple AC switch circuit triggered by leakage current 11. Household dimmable desk lamp circuit |

|---|

(III) Comprehensive Training of PLC and Inverter

(1) PLC Basic Skills Training

- PLC cognitive training (software and hardware structure, system composition, basic instruction practice, wiring, programming and downloading, etc.)

- Typical motor control practical training (inching, self-locking, forward and reverse rotation, star-delta switching starting, etc.)

- PLC simulation training

(2) PLC Simulation Control Application Training

| 4. Digital display control 5. Buzzer control (priority, numerical operation, with sound effect function) 6. Tianjin Tower light control (flickering, emitting, flowing water type) 7. Musical fountain control (with sound effect function) 8. Crossroad traffic light control 9. Water tower water level control 10. Automatic feeding and loading system control 11. Four-section conveyor belt control 12. Assembly line control 13. Multiple liquid mixing device control |

14. Automatic forming machine control 15. Fully automatic washing machine control 16. Electroplating production line control 17. Automatic rolling mill control 18. Mail sorting machine control 19. Vending machine control 20. Manipulator control 21. Four-story elevator control 22. Machining center control |

|---|

(3) PLC Physical Control Training

| 1. Stepper motor motion control 2. DC motor control |

|---|

(4) Comprehensive Application Skills Training of PLC and Inverter

| 1. Inverter function parameter setting and operation 2. Inverter alarm and protection functions 3. External terminal inching control 4. Inverter control of motor forward and reverse rotation 5. Multi-speed selection variable frequency speed regulation 6. Inverter stepless speed regulation 7. Variable frequency speed regulation based on external analog quantity (voltage/current) control mode 8. Instantaneous power failure start control 9. PID variable frequency speed regulation control 10. PLC control of motor forward and reverse rotation via inverter external terminals 11. PLC control of motor running time via inverter external terminals |

12. Multi-speed based on PLC digital quantity control mode 13. Inverter open-loop speed regulation based on PLC communication mode 14. Speed closed-loop control based on PLC communication mode 15. Simulation of inverter constant pressure water supply system 16. Basic instruction programming practice based on touch screen control mode 17. LED control based on touch screen control mode 18. Temperature PID control based on touch screen control mode 19. PLC, touch screen and inverter communication control 20. 485 bus network communication technology based on MCGS |

|---|

V. Equipment Configuration

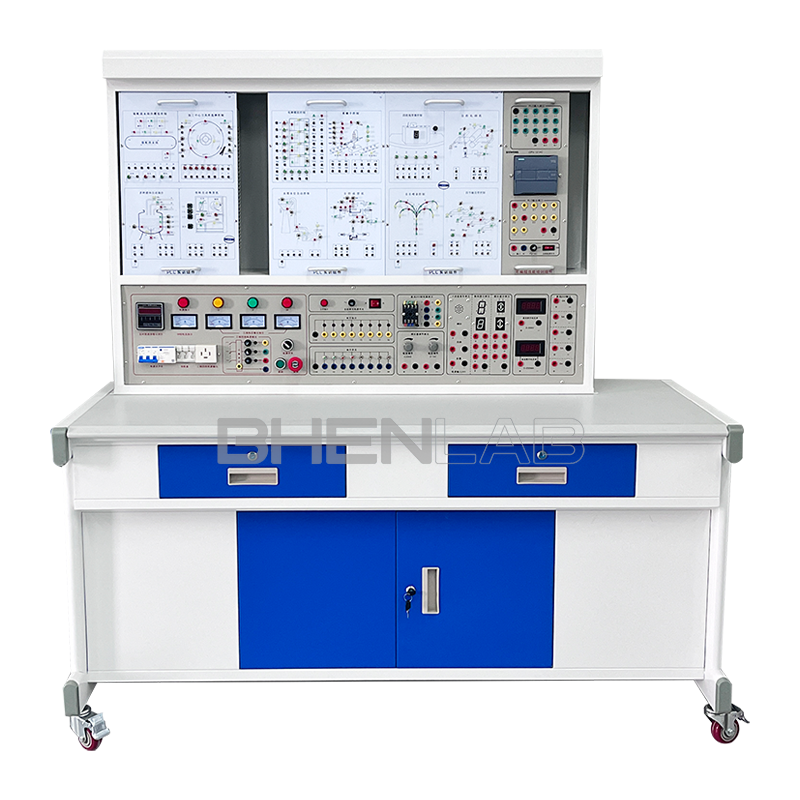

(I) DW01 Power Supply and Instrument Control Panel

The control panel is of iron double-layer matte dense pattern spray structure with an aluminum panel. It provides AC power, high-voltage DC power, low-voltage DC power, and various testing instruments for experiments. The specific functions are as follows:

-

Main control function board

(1) Three-phase four-wire power input, after passing through the leakage protector, through the main switch, operated by contactor via start and stop buttons.

(2) Equipped with three 450V pointer-type AC voltmeters to indicate the three-phase input voltage.

(3) Timer and alarm recorder (service manager), which is usually used as a clock, with functions of setting experiment time, timing alarm, and power cut-off; it can also automatically record the total number of leakage alarms and instrument over-range alarms caused by wiring or operation errors, providing a unified standard for the assessment of students’ training skills. -

AC and DC power supplies

(1) Excitation power supply: DC 220V/0.5A, with short-circuit protection.

(2) Armature power supply: one DC 0~220V/2A continuously adjustable power supply, with short-circuit protection.

(3) DC stabilized power supply: two ±12V/0.5A, one +5V/0.5A, with short-circuit soft cut-off automatic recovery protection function.

(4) AC power supply: ① Equipped with a transformer, the primary side of the transformer can be connected to 220V or 380V AC power according to different wiring, and after closing the switch, the secondary side of the transformer can output AC voltages of 36V, 110V, 20V, 20V, 12V, and 6.3V; ② Equipped with a single-phase voltage regulator, which can obtain adjustable AC voltage of 0~250V; ③ The control panel is equipped with a single-phase three-pole 220V power socket and a three-phase four-pole 380V power socket. -

AC and DC instruments

(1) AC voltmeter: one 0~500V mirror AC voltmeter, with an accuracy of 1.0 class.

(2) AC ammeter: one 0~5A mirror AC ammeter, with an accuracy of 1.0 class, with functions of over-range alarm, indication, and total power cut-off.

(3) Power and power factor meter: composed of a microcomputer, high-precision A/D conversion chip, and full digital display circuit. It realizes man-machine 对话功能 control mode through key control and digital display window. To improve the measurement range and accuracy, it is divided into eight ranges in hardware and software, with automatic judgment and automatic range switching. The power measurement accuracy is 1.0 class, the voltage and current ranges are 450V and 5A respectively. When measuring the power factor, it can automatically judge the load nature (inductive displays “L”, capacitive displays “C”, pure resistance does not display), and can store 15 groups of data for viewing at any time.

(4) DC voltmeter: one DC digital voltmeter, measuring range 0~300V, three and a half digital display, input impedance 10MΩ, accuracy 0.5 class.

(5) DC ammeter: one DC digital ammeter, measuring range 0~5A, three and a half digital display, accuracy 0.5 class, with functions of over-range alarm, indication, and total power cut-off. -

Rectifier diodes: four IN5408

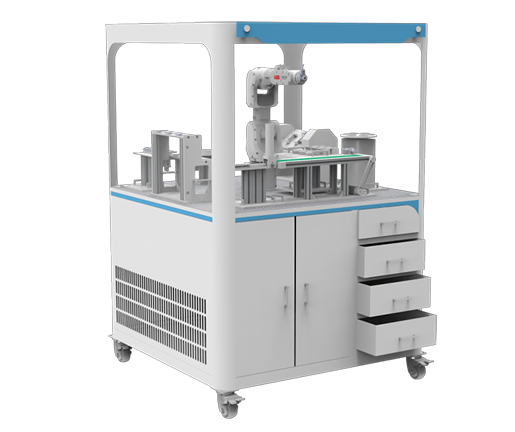

(II) Experiment Table

The experiment table is of iron double-layer matte dense pattern spray structure, with a fireproof, waterproof, and wear-resistant high-density board tabletop, a solid structure, and an elegant appearance. There are two drawers (with locks) on each side of the table.

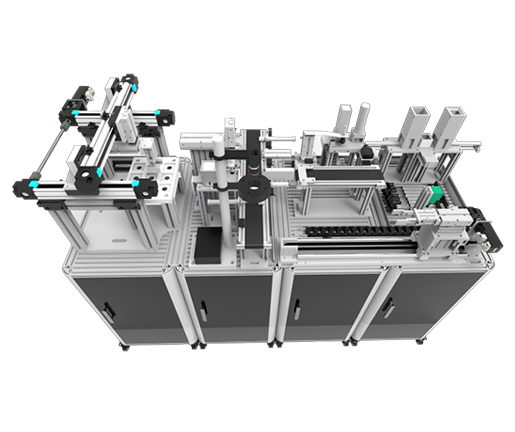

(III) Experiment Components

-

DW-01 Maintenance Electrician Training Component (I)

The hanging box is equipped with thermal relays, AC contactors (380V), button indicators (6.3V), terminal blocks, etc. -

DW-02 Maintenance Electrician Training Component (II)

The hanging box is equipped with screw-type fuses, plug-in fuses, low-voltage circuit breakers, time relays, AC contactors, terminal blocks, etc. -

DW-03 Maintenance Electrician Training Component (III)

The hanging box is equipped with screw-type fuses, changeover switches, solenoid valves, cross switches, travel switches, etc. -

DW-04 Maintenance Electrician Training Component (V)

The hanging box is equipped with AC overcurrent relays, DC overcurrent relays, rectifiers, fluorescent tubes, terminal blocks, etc. -

DW-05 Electrical Skills Training Component (IV)

Provides two groups of 90Ω×2/1.3A disk resistors; one group of 900Ω×2/0.41A disk resistors. -

PLC Host Hanging Box

Equipped with Mitsubishi FX3U-48MR host, integrating digital I/O (24 digital inputs, 24 digital outputs), RS-422 communication port, SC-09 communication programming cable, and switching input/output ports, switches, etc. It is randomly equipped with simulation teaching software and industrial control configuration software. -

PLC Training Demonstration Hanging Box

| Serial Number | Number | Control Object Training Module | Training Teaching Objectives |

|---|---|---|---|

| 1 | BH1 | Buzzer/Musical Fountain | Master the programming method of conditional judgment control instructions by monitoring and controlling the answering sequence of each group in the answering system; master the programming method of loop instructions by controlling the “water flow” and music cycle in the musical fountain control system. |

| 2 | BH2 | Assembly Line/Crossroad Traffic Light | Master the programming method of sequence control instructions by controlling the sequential processing of “production line” and the road condition signals of crossroad traffic lights. |

| 3 | BH3 | Water Tower Water Level/Tianjin Tower Light | Understand the programming method of simple logic control instructions by judging the change process of “water tower water level” and “reservoir water level”. Master the programming method of shift register instructions by controlling the shifting of Tianjin Tower light flashing process. |

| 4 | BH4 | Automatic Feeding and Loading/ Four-Section Conveyor Belt | Master the programming method of more complex logic control instructions by controlling the start-stop and transmission status of the conveyor belt and the flow direction and flow of goods in the automatic feeding and loading system. |

| 5 | BH5 | Multiple Liquid Mixing Device | Master the programming methods of conditional judgment instructions and various types of timer instructions by controlling the proportion of different liquids and the stirring time in the “liquid mixing device”. |

| 6 | BH6 | Vending Machine | Master the programming methods of various counter instructions and comparison output instructions by identifying the number of coins inserted by users and controlling the in and out of various “goods” in the vending machine. |

| 7 | BH7 | Automatic Rolling Mill/Mail Sorter | Master the programming methods of numerical operation instructions and interrupt instructions by identifying the quantity and type of incoming materials (“ingots” and “mails”) in the automatic rolling mill and mail sorter, and controlling the start-stop sequence of various actuators (such as “motors”). |

| 8 | BH8 | Manipulator Control/Automatic Forming Machine | Master the ability to write simple logic control programs in a complete industrial application system by controlling the “position” of the manipulator and the “cylinder position” of the automatic forming machine in various directions. |

| 9 | BH9 | Machining Center | Master the ability to write more complex logic control programs in a complete industrial application system by controlling the operation direction of “motors” in various directions in the machining center and the process of tool in-out and tool change in the “tool magazine”. |

| 10 | BH10 | Four-Story Elevator | Preliminarily master the comprehensive knowledge of the working process of PLC control system, such as analysis, I/O allocation, design of I/O wiring diagram, wiring, programming, and debugging, by comprehensively controlling a complete four-story elevator model. |

-

Inverter Training Hanging Box

Equipped with Mitsubishi FR-D720 inverter, with RS485 communication interface and BOP operation panel. -

Touch Screen Training Hanging Box

Touch screen training component: 7-inch Eview500, 256 colors, to understand the functions and usage methods of industrial touch screens, master the communication knowledge with PLC, and master the implementation methods of reset, set, alternate function keys, graphic (curve) display, and dynamic picture tracking in the touch screen. -

One set of industrial control configuration software:

Open the software programming environment, and any training can edit intuitive and dynamic configuration bar charts with good digital effects, and carry out dynamic tracking teaching of training. -

One set of PLC simulation training software:

(1) Real-time display of PLC operation status through PLASH virtual environment.

(2) Can realize PLC virtual wiring and check wiring errors.

(3) PLC programming training, PLC program writing and testing functions.

(4) Realize PLC operation simulation and check error programs. -

Three-phase squirrel-cage motor AC380V (Y) (with speed relay)

-

Three-phase squirrel-cage motor AC380V (△)

-

Two-speed asynchronous motor AC380V (△/Y)

BOH-G203 High-performance Advanced Maintenance Electrician Skills Training and Assessment Device

Schlagwörter: electrical teaching equipmentMaintenance ElectricianKategorie: ElektrikerArtikelnummer: n. v.

Marke: BHENLAB