I. Overview

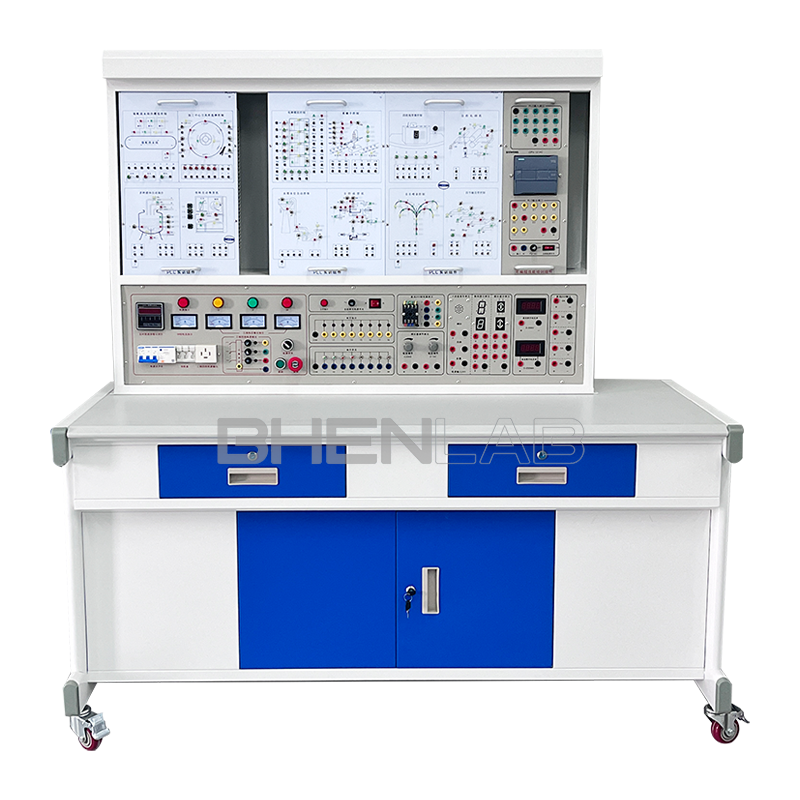

This device is designed in accordance with the requirements of the “Worker Grade Standard” and “Vocational Skill Appraisal” issued by the Ministry of Labor and Social Security. It is applicable to the electrical control circuits required by the textbooks Primary Maintenance Electrician, Intermediate Maintenance Electrician, and Advanced Maintenance Electrician. Through training with the PLC programmable controller, frequency converter, and corresponding training modules equipped with the device, users can quickly master the practical application technologies and operational skills required by the courses. It is targeted, practical, scientific, and advanced, meeting the requirements of the assessment outline for intermediate and advanced maintenance electricians. It is an ideal equipment for skill assessment of intermediate and advanced maintenance electricians in various labor vocational skill appraisal departments, colleges and universities, and technical schools.

II. Device Features:

- The components of the electrical control circuit are mounted on a mounting plate (as a hanging board), which is easy to operate and replace, facilitating function expansion or development of new training. The selection of operation contents is typical and practical;

- The operation platform only needs a three-phase four-wire AC power supply to be put into use;

- The control circuit for skill training and the specially designed small motor can simulate various electrical drive systems in factories, and can meet the technical requirements of maintenance electricians for installation, debugging, fault analysis, and troubleshooting;

- The device is equipped with voltage-type and current-type leakage protectors to ensure the personal safety of operators;

- All components are led to terminals through wires, and students only need to wire on the terminals, which is beneficial to protect the components;

- Wiring is done through wire troughs for process wiring training.

- It has a timer and alarm recorder, providing a unified standard for the assessment of students’ practical skills.

III. Technical Performance:

- Input voltage: Three-phase four-wire (or three-phase five-wire) ~380V±10% 50Hz

- Working environment: Temperature -10~+40℃; Relative humidity <85% (at 25℃); Altitude <4000m

- Device capacity: <1.5KVA

- Weight: 100Kg

- Overall dimensions: 1700×700×1630mm³

- Leakage protection action current: ≤30mA; Leakage protection action time: ≤0.1s.

IV. Basic Configuration and Functions of the Device

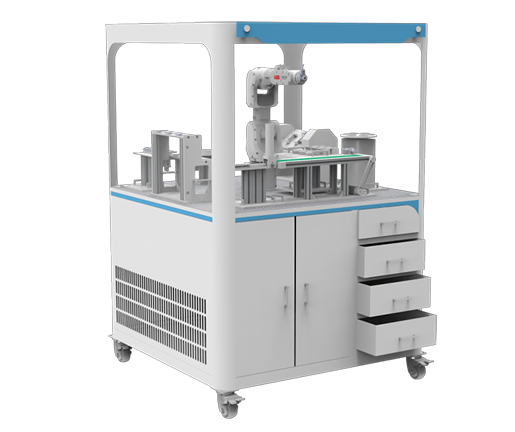

(I) BH02 Power Control Box

The main control screen has a double-layer iron matte dense-grain spray structure with an aluminum panel.

(II) Resources Equipped with the Main Control Function Board

- Three-phase four-wire power input, after passing through the leakage protector, goes through the main switch, controls the contactor on/off through start and stop buttons, and is equipped with an emergency stop control button;

- The control screen is equipped with a 450V pointer-type AC voltmeter, which can observe the three-phase grid voltage through a band switch;

- Timer and alarm recorder (service manager), which is usually used as a clock, with functions such as setting time, timing alarm, and cutting off power; it can also automatically record the total number of leakage alarms and power short circuits caused by wiring or operation errors, providing a unified standard for the assessment of students’ practical skills;

- AC circuit measuring meter: 8-digit LED display, which can simultaneously measure current I, voltage V, power KW, electric energy KWh, and working time T in the working circuit. Accuracy: 1.0 class.

- AC low-voltage power supply: Equipped with a transformer, with primary 220V, secondary 26V and 6.3V AC voltage. 6.3V is used for the signal indicator power supply, and 26V is used for the AC power supply of the rectifier circuit in energy-consuming braking;

- 4 diodes (model 5408) for the rectifier circuit of energy-consuming braking;

- Three 75Ω/75W resistors for motor step-down starting, and one 10Ω/25W resistor for asynchronous motor energy-consuming braking.

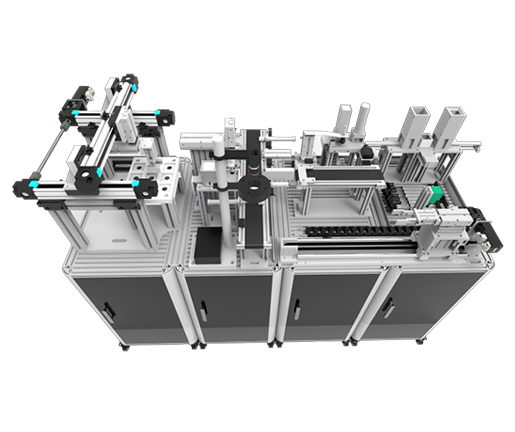

(III) Training Desk

The training desk has a double-layer iron matte dense-grain spray structure, with a fireproof, waterproof, and wear-resistant high-density board desktop. It has a solid structure and an elegant appearance. The table is equipped with two drawers (with locks) on the left and right, and a cabinet, which can be used to place hanging parts and training items respectively.

V. Training Projects

| 1. Direct start control circuit of three-phase asynchronous motor 2. Inching control circuit of three-phase asynchronous motor 3. Self-locking control circuit of three-phase asynchronous motor 4. Button interlocking forward and reverse rotation control circuit of three-phase asynchronous motor 5. Contactor interlocking forward and reverse rotation control circuit of three-phase asynchronous motor 6. Double interlocking forward and reverse rotation control circuit of three-phase asynchronous motor 7. Automatic reciprocating control circuit of three-phase asynchronous motor workbench 8. Sequential start and stop control circuit of two three-phase asynchronous motors 9. Two-place control circuit of three-phase asynchronous motor 10. Y-△ control by contactor 11. Y-△ control by time relay 12. One-way start reverse connection braking control circuit of three-phase asynchronous motor 13. One-way start energy-consuming braking control circuit of three-phase asynchronous motor with transformerless half-wave rectification 14. One-way start energy-consuming braking control circuit of three-phase asynchronous motor with transformer full-wave rectification 15. Forward and reverse start energy-consuming braking control circuit of three-phase asynchronous motor 16. Capacitor start control circuit of single-phase squirrel-cage motor 17. Manual speed change control circuit of two-speed AC asynchronous motor 18. Automatic speed change control circuit of two-speed AC asynchronous motor 19. Y-△ start control circuit with power-off delay DC energy-consuming braking 20. Forward and reverse energy-consuming braking control circuit of three-phase asynchronous motor 21. Forward and reverse start reverse connection braking control circuit of three-phase asynchronous motor 22. Electrical control circuit of C620 lathe 23. Electrical control of electric hoist 24. Control circuit of Y3150 gear hobbing machine 25. Basic instruction operation of programmable controller 26. LED digital display control 27. Simulation of Tianjin Tower light control |

28. Simulation of crossroads traffic lights 29. Simulation of manipulator action 30. Simulation of four-section conveyor belt 31. Simulation of assembly line control 32. Simulation of five-phase stepping motor control 33. Simulation of water tower water level control 34. Simulation of liquid mixing device control 35. Simulation of mail sorter control 36. Simulation of rolling mill control 37. Simulation of automatic forming machine control 38. Simulation of automatic feeding and loading control 39. Simulation of fully automatic washing machine control 40. Simulation of electroplating production line control 41. PLC-controlled forward and reverse rotation control of three-phase asynchronous motor 42. PLC-controlled Y-△ start control of three-phase asynchronous motor 43. PLC-controlled step-down start control of three-phase asynchronous motor 44. PLC-controlled energy-consuming braking control of three-phase asynchronous motor 45. Frequency converter function parameter setting and operation 46. Frequency converter alarm and protection functions 47. Multi-speed selection variable frequency speed regulation 48. External terminal inching control 49. Control of motor forward and reverse rotation 50. Control of motor running time operation 51. Parameter setting of frequency converter for instantaneous power failure 52. External voltage variable frequency speed regulation 53. External current variable frequency speed regulation 54. Frequency conversion open-loop speed regulation of three-phase asynchronous motor 55. PLC-controlled frequency converter speed regulation |

VI. Configuration of Training Components

| Serial Number | Hanging Box Number | Name of Training Module | Quantity | Remarks |

| 1 | BH-06 | Maintenance Electrician Training and Assessment Component (I) | 1 piece | Provides 2 capacitors, 1 AC solenoid valve, 1 AC contactor, 3 thermal relays |

| 2 | BH-07 | Maintenance Electrician Training and Assessment Component (II) | 1 piece | Provides 1 air switch, 2 3P fuses, 3 AC contactors |

| 3 | BH-08 | Maintenance Electrician Training and Assessment Component (III) | 1 piece | Provides 2 power-on delay time relays, 1 power-off delay time relay, 4 travel switches, 6 buttons of various colors |

| 4 | BH-09 | Maintenance Electrician Training and Assessment Component (IV) | 1 piece | Provides 4 AC contactors |

| 5 | BH-PLC | PLC Programmable Controller Training Component | 1 piece | Provides Siemens SMART, CPU SR40 host |

| 6 | PLC Training Modules (16 pieces) | 1 set | Familiar with the usage and programming methods of PLC instructions | |

| 7 | BH-BPQ | Frequency Converter Training Component | 1 piece | Provides Siemens V20 frequency converter, which can perform communication training with PLC |

| 8 | SC-09 Programming Cable | 1 piece | Used for communication between PLC host and PC | |

| 9 | Programming Software | 1 set | Provides Siemens programming software | |

| 10 | Mesh Practical Operation Board | 1 piece | By matching components, students can fix, install, layout, wire, and debug on the mesh board by themselves, which can cultivate students’ practical ability and operational skills. The mesh board can also be used as an expansion module for training projects. | |

| 11 | Single-Phase Capacitor-Start Motor | 1 unit | AC 220V | |

| 12 | Three-Phase Squirrel-Cage Asynchronous Motor | 1 unit | AC 380V/Y (with speed relay) | |

| 13 | Three-Phase Two-Speed Asynchronous Motor | 1 unit | AC 380V/△/YY |

PLC Training Modules (Complete Set)

| Serial Number | Module Number | Name of Training Module | Serial Number | Module Number | Name of Training Module |

| 1 | PLC-M | Basic Instruction Practice (Siemens Host) | 9 | PLC-008 | Water Tower Water Level |

| 2 | PLC-001 | LED Digital Display | 10 | PLC-009 | Liquid Mixing Device |

| 3 | PLC-002 | Tianjin Tower Lights | 11 | PLC-010 | Mail Sorter |

| 4 | PLC-003 | Crossroads Traffic Lights | 12 | PLC-011 | Rolling Mill |

| 5 | PLC-004 | Manipulator | 13 | PLC-012 | Automatic Forming Machine |

| 6 | PLC-005 | Four-Section Conveyor Belt | 14 | PLC-013 | Automatic Feeding and Loading |

| 7 | PLC-006 | Assembly Line | 15 | PLC-014 | Fully Automatic Washing Machine |

| 8 | PLC-007 | Five-Phase Stepping Motor | 16 | PLC-015 | Electroplating Production Line |