I. Product Overview

This device is specially developed for civil engineering and water conservancy-related majors such as water supply and drainage engineering, building electrical engineering, building intelligent equipment, building equipment, and municipal engineering offered by vocational colleges. The device adopts an engineering object system design training model based on the characteristics of water supply and drainage engineering systems in residential and industrial places in the construction industry. Through the operation training of this device, students’ comprehensive abilities in mastering water supply and drainage equipment installation and control can be assessed, such as pipe cutting and connection, pipeline installation, equipment installation, electrical installation, equipment wiring, programming control, fault troubleshooting, etc. At the same time, it can cultivate students’ teamwork ability, work efficiency, quality awareness, safety awareness, professional ethics and professional literacy.

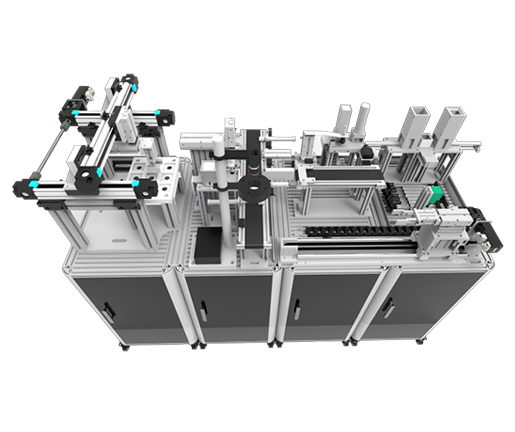

II. System Structure and Composition

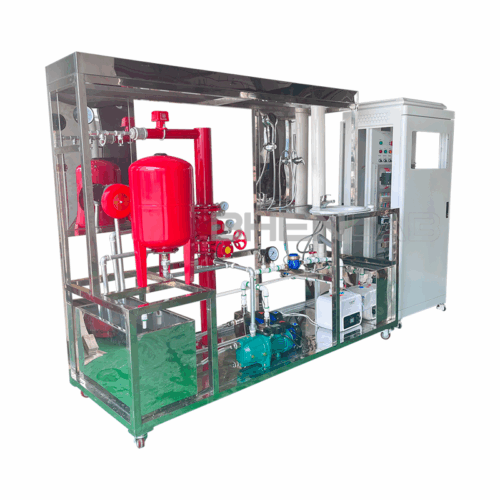

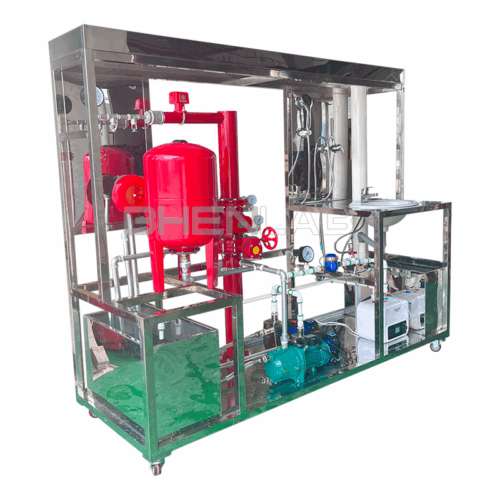

The overall water supply and drainage object model is designed with a stainless steel frame. The main water supply and drainage pipeline equipment is installed on the steel frame base, featuring an open structure. It consists of five parts: domestic water supply system, fire water supply system, hot water supply system, drainage system and control system.

The domestic water supply system mainly includes a water supply tank, water supply pump, water supply pipeline, pressure transmitter, pulse water meter, faucet and shower head. The pipeline is designed with stainless steel composite pipes, allowing operations such as cutting, installation and water flow test of stainless steel composite pipes. Through the control system, the frequency conversion constant pressure water supply function of the domestic water supply system can be realized, as well as functions like single pump frequency conversion control or dual pump switching control. The pulse water meter can be used to measure water consumption.

The fire water supply system mainly includes a water supply tank, sprinkler pump, pressure stabilizing tank, wet alarm valve, pressure switch, water flow indicator, fire water supply pipeline, closed sprinkler head, etc. The pipeline is designed with galvanized pipes, enabling operations such as cutting, threading, installation and water flow test of galvanized pipes. The sprinkler fire extinguishing function can be realized through the control system.

The hot water supply system mainly includes an electric heating boiler, hot water supply pipeline, faucet and shower head. The pipeline is designed with PPR pipes, allowing operations such as cutting, welding, installation and water flow test of PPR pipes, and temperature adjustment and control of the boiler.

The drainage system mainly includes a sewage tank, liquid level sensor, drainage pump, drainage pipeline and water treatment unit. The drainage pipeline is mainly designed with UPVC pipes, enabling operations such as cutting, bonding, installation and water flow test of UPVC pipes. Combined with the control system, it can realize functions such as water level detection of the sewage tank and start-stop control of the drainage pump.

The automatic control system for water supply and drainage mainly includes an electrical control cabinet, touch screen, operation switches, working status indicators, PLC controller, frequency converter, low-voltage electrical appliances, water pumps, water meters, sensors (float level gauge, pressure switch, water flow indicator, signal butterfly valve, pressure transmitter), configuration monitoring software, etc. The automatic control function of the water supply and drainage system can be realized through the control system.

III. Main Technical Performance

- Working power supply: Three-phase four-wire AC380V±10% 50Hz;

- Overall dimensions of the water supply and drainage model: 2.25m×0.79m×1.9m (length×width×height);

Overall dimensions of the electrical control cabinet: 0.8m×0.6m×1.8m (length×width×height); - Material of the water supply and drainage model: Stainless steel;

- Total power consumption of the device: <4.5KVA;

- The bottom of the device is equipped with casters with brakes, facilitating the movement and fixation of the device;

- Safety protection measures: Equipped with grounding protection, leakage and overload protection, misoperation protection functions; Safety complies with relevant national standards, and all materials meet environmental protection standards.

IV. Professional Abilities That Can Be Assessed Through Project Task Implementation

- Drawing of system completion diagrams and control electrical schematic diagrams;

- Pipe processing and connection:

Cutting, threading, welding and connection of galvanized pipes, stainless steel composite pipes, PPR pipes and UPVC pipes. - Installation of accessories and devices:

Complete the installation of pipeline accessories in the domestic water supply system, fire water supply system, hot water supply system and drainage system; Complete the installation of plumbing devices such as water pumps, pressure transmitters, water meters, float level gauges, signal butterfly valves, wet alarm valve groups, water flow indicators, closed sprinklers, terminal water test devices, faucets and showers. - Pipeline pressure test and water flow test;

- Electrical design, installation and wiring:

Installation and wiring of water pumps, distribution cabinets, controllers, command components and operation components. - Control program design and debugging:

(1) Frequency conversion control program design and debugging;

(2) Meter reading and billing program design;

(3) Sprinkler fire extinguishing control program design;

(4) Water supply and drainage monitoring program design;

(5) Configuration monitoring system design.

V. Basic Configuration

- Equipment Framework

| Serial Number | Equipment Name | Specification or Model | Quantity | Unit | Remarks |

| Stainless Steel Frame | 225cm×79cm×198cm | 1 | Set | ||

| Sewage Treatment Unit | Organic glass | 1 | Piece | ||

| Wet Alarm Valve Group | Including retarder, pressure switch and water flow alarm bell | 1 | Set | ||

| Water Flow Indicator | Sensitivity: 15-37.5L/min | 1 | Piece | ||

| Glass Ball Sprinkler Head | 68℃ temperature class | 2 | Pieces | ||

| Signal Butterfly Valve | Dry contact output | 1 | Piece | ||

| Fire Water Pump | Three-phase AC380V, power: 0.55KW, head: 33m, flow rate: 130 L/min | 1 | Set | ||

| Frequency Conversion Magnetic Drive Pump | Three-phase AC380V, power: 0.37KW, head: 12m, flow rate: 20L/min | 2 | Sets | ||

| Drainage Pump | Single-phase AC220V, power: 95W, head: 9m, flow rate: 18L/min | 1 | Set | ||

| Air Pressure Tank | Volume 50L | 1 | Piece | ||

| Pressure Transmitter | Range 0-200KPa | 1 | Piece | Diffused silicon | |

| Electric Heating Boiler | Capacity 7L, power 2KW | 1 | Set | ||

| Bathroom Vanity Basin | 50 cm×45 cm×20 cm | 1 | Piece | ||

| Universal Drain | Universal part | 1 | Piece | ||

| Water Tap | Mixed type | 1 | Piece | ||

| Shower Head | Universal part | 1 | Piece | ||

| Mixing Valve | Universal part | 1 | Piece | ||

| Float Level Sensor | High, medium and low three gears | 1 | Piece | ||

| Pulse Water Meter | 0.01 cubic meter/pulse | 1 | Piece |

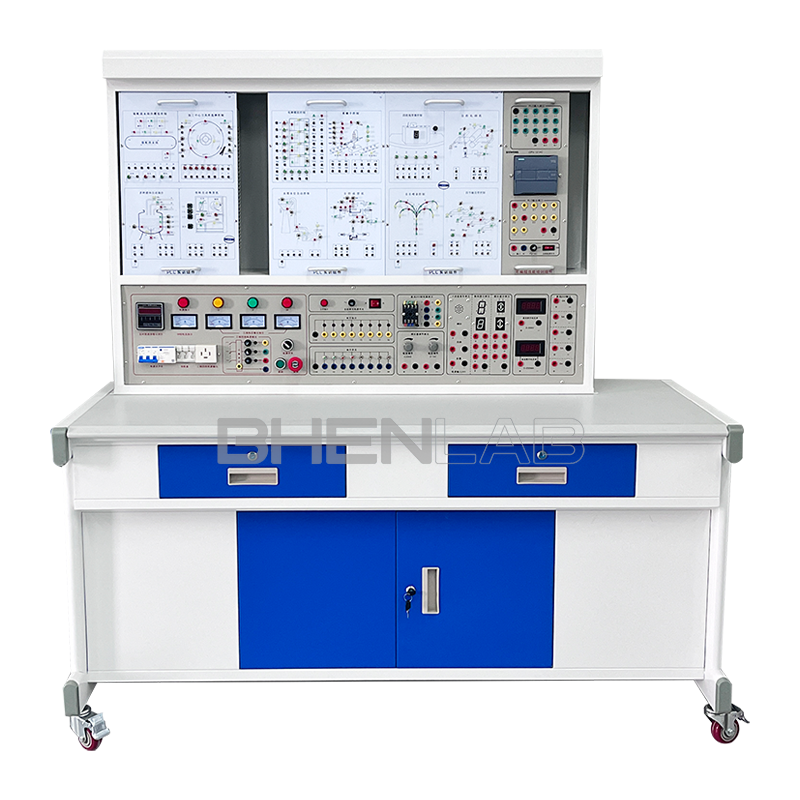

- Basic Configuration of Electrical Control Cabinet

| Serial Number | Equipment Name | Specification or Model | Quantity | Unit | Remarks |

| Siemens PLC Controller | CPU224XP, 14DI/10DO, 2AI/1AO | 1 | Piece | ||

| Siemens Frequency Converter | MM420, three-phase 380V input, 0.75kW, with BOP panel | 1 | Set | ||

| Siemens Touch Screen | 7-inch, color, high resolution | ||||

| Configuration Software | ForceControl 6.0 | 1 | Set | ||

| Low-Voltage Electrical Appliances | Small relays, AC contactors, thermal overload relays | 1 | Set | ||

| Air Switch | With leakage protector | 1 | Piece | ||

| Fuse | 15A | 3 | Pieces | ||

| Operation Switch | 2-position | 6 | Pieces | ||

| Switching Power Supply | Output: DC24V | 1 | Piece | ||

| Working Status Indicator | Working voltage: DC24V | 7 | Pieces | ||

| Profile Computer Desk | 60cm×60cm×80cm | 1 | Piece | Computer to be prepared by users |

- Pipes, Fittings and Supporting Tools

| Serial Number | Name | Main Components | Quantity | Remarks |

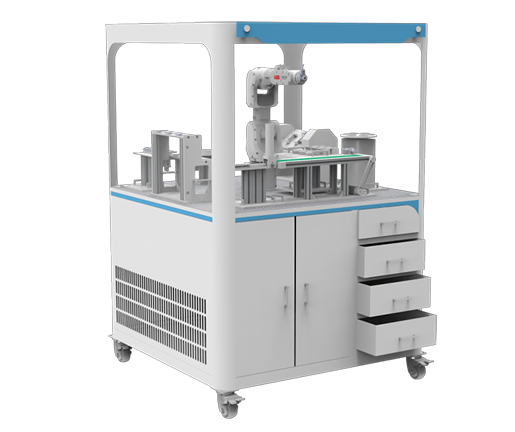

| 1 | Deluxe Tool Cart | Designed with steel plates, equipped with drawers and cabinets, movable | 1 set | |

| 2 | Pipes and Fittings | Including short-handle ball valves, copper ball valves, butterfly ball valves, brass gate valves, copper check valves, galvanized reducing joints, galvanized 90° elbows, galvanized union joints, galvanized straight-through joints, galvanized three-way joints, PVC-U pipes, PVC vent caps, PVC special-shaped smooth three-way joints, PVC single-socket, PVC double-socket water storage pipes, PP-R pipes, 90° elbows, female threaded three-way joints, equal-diameter three-way joints, female threaded elbows, male threaded joints, globe valves, external thread straight-through joints, internal thread straight-through joints, internal thread three-way joints, stainless steel internal thread three-way joints, elbows, stainless steel internal thread elbows, stainless steel external thread straight-through, copper adapters, copper union joints, angle valves, braided hoses, metal conduits, metal conduit joints, 2-inch galvanized pipes, 1-inch galvanized pipes, 3/4-inch galvanized pipes, 1/2-inch galvanized pipes, stainless steel composite pipes, black insulation pipes, etc. | 1 set | |

| 3 | Supporting Tools | Including pipe threaders, pipe vices (with brackets), galvanized pipe cutters, hot-melt machines, PPR pipe scissors, composite pipe cutters, hacksaws, saw blades, PVC glue, tape measures, wrenches, pipe wrenches, needle-nose pliers, Teflon tape, hexagon socket wrenches, markers, Phillips screwdrivers, flat-blade screwdrivers, patch panels, insulating gloves, insulating boots, multimeters, wire strippers, diagonal pliers, solder wire, electric soldering irons, soldering iron stands, scissors, manual pressure test pumps, etc. | 1 set |