PLC programmable controller is a new type of industrial control device developed on the basis of microprocessors. With the characteristics of small size, strong function, high reliability and convenient application and installation, it quickly occupied a dominant position in China’s industrial control and continues to develop. In response to this development trend, colleges and universities as well as various vocational and technical schools across the country have incorporated PLC teaching into their teaching tasks, making it a compulsory course for majors in electronics, electrical engineering and industrial automation. The PLC programmable experiment system is a new generation of PLC teaching product developed in accordance with this teaching requirement. Since its launch, it has been highly praised by teaching teachers and experts from various colleges and universities. The complete set of devices has a reasonable design, powerful functions and simple operation, which is of great help for students to understand and master the control principles and operation methods of programmable controllers and accelerate the learning of PLC programming methods. It is an ideal tool in PLC teaching.

System Composition

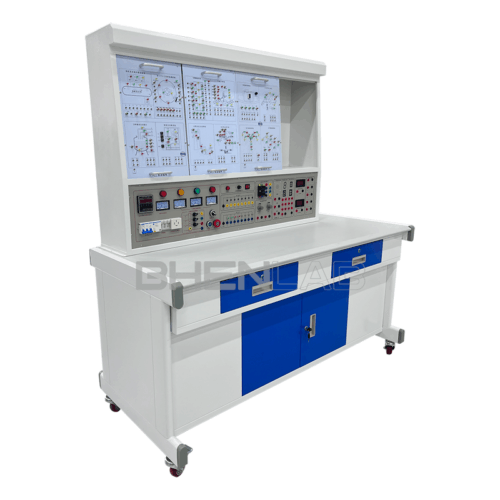

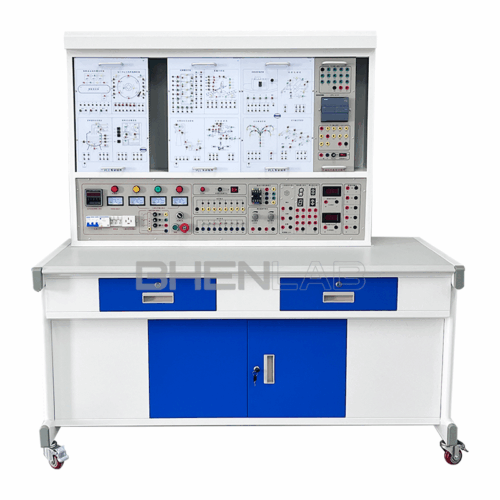

1.PLC programmable controller experiment bench

2.PLC programmable controller demonstration device

3.PLC programmable controller operation desk

4.Programming application software

5.PLC and transfer communication cable or manual controller (self-provided)

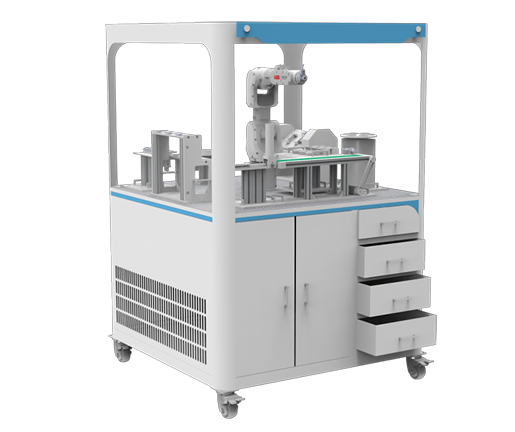

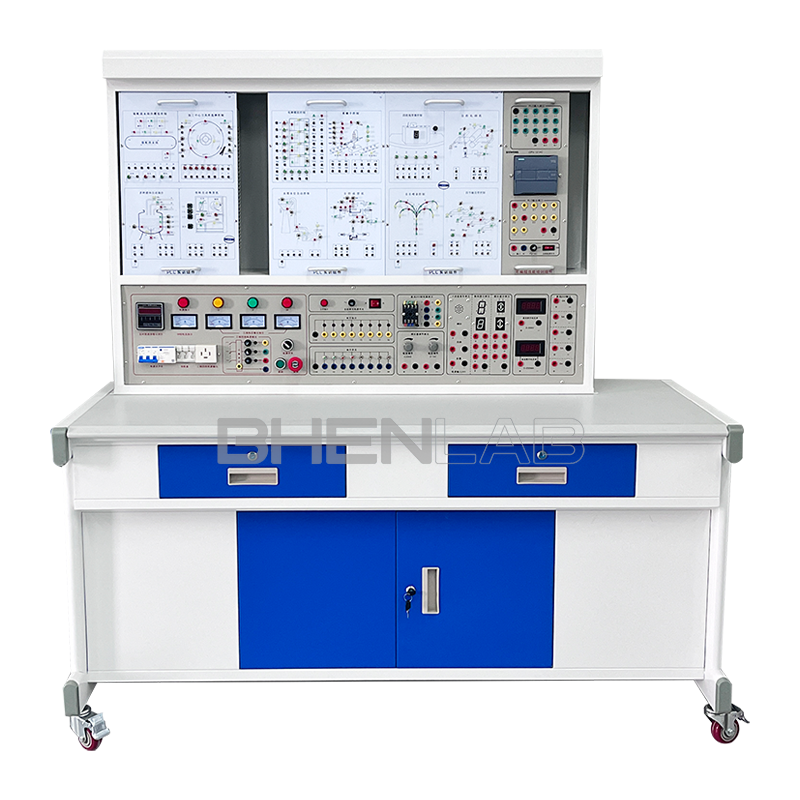

PLC Programmable Controller Experiment Bench

1. Functions and Features

1.The experiment bench includes:

1.AC power input area

2.PLC host

3.LED light-emitting tubes, indicator lights

4.Output load indication

5.Input analog switches (buttons and switches)

6.LED nixie tubes, buzzers

7.DC regulated power supply: 5V1A, 24V2A

8.PLC input and output ports

9.DC motor, relay

2.The input and output of the PLC host are led to the panel. The input can be connected to analog input switches, travel switches or photoelectric switches, etc. The output can be connected to the indicator lights, nixie tubes, relays, DC motors and buzzers on the panel, and can also be connected to the demonstration device, which can be applied to actual industrial control.

3.The PLC host generally adopts the original Japanese Mitsubishi series host. Other models of hosts can also be equipped if required by users.

4.The experiment bench itself is equipped with a 24V2A power supply, which can be directly used for output loads, or connected to the demonstration device interface or other corresponding devices.

5.The connection between the PLC experiment bench and the demonstration device can use self-locking connectors for single-line point-by-point connection to improve hands-on and thinking abilities and deepen the understanding of the structure and function of PLC. It can also be connected at one time through a flat cable to improve the speed of experimental wiring. Compared with the single connection method of other manufacturers, it has absolute advantages.

6.It can complete basic experiments and application experiments of PLC control principles, and can be used for real industrial control.

2. Experiment Projects

- AND, OR, NOT logic function experiments

- Timer and counter function experiments

- Jump and branch function experiments

- Shift register experiments

- Data processing function experiments

- Differential and bit operation experiments

- PLC automatic control of traffic lights

- PLC automatic control of water tower water level

- PLC automatic control of automatic forming machine

- PLC automatic control of automatic rolling mill

- PLC automatic control of multiple liquid automatic mixing

- PLC automatic control of automatic feeding and loading system

- PLC automatic control of mail sorting machine

- PLC automatic control of elevator

- PLC automatic control of manipulator

- PLC simulation control of five-phase stepping motor

- PLC automatic control of automatic beverage vending machine

- PLC automatic control of automatic washing machine system

- PLC automatic control of electroplating workshop production system

- PLC automatic control of machining center tool magazine selection

- LED nixie tube experiments

- PLC automatic control of Tianjin Tower lights

- Additional basic experiment contents

3. Technical Parameters

- PLC host selection: Mitsubishi FX3U-48MR

- Output voltage: DC 24V, indicated by a voltmeter

- Programming with application software

- Power input: AC 220V, 50Hz

- Current ≥ 2A, with overload protection

- Overall dimensions: 170 X 70 X 140 cm

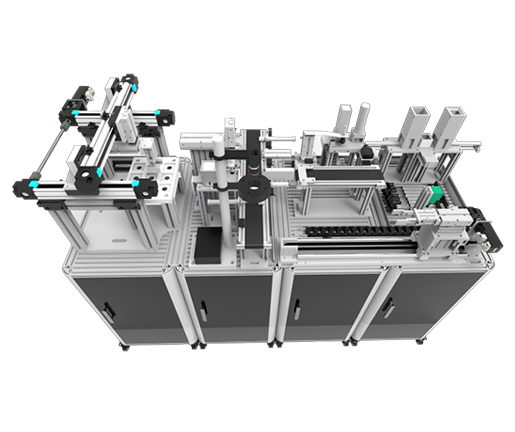

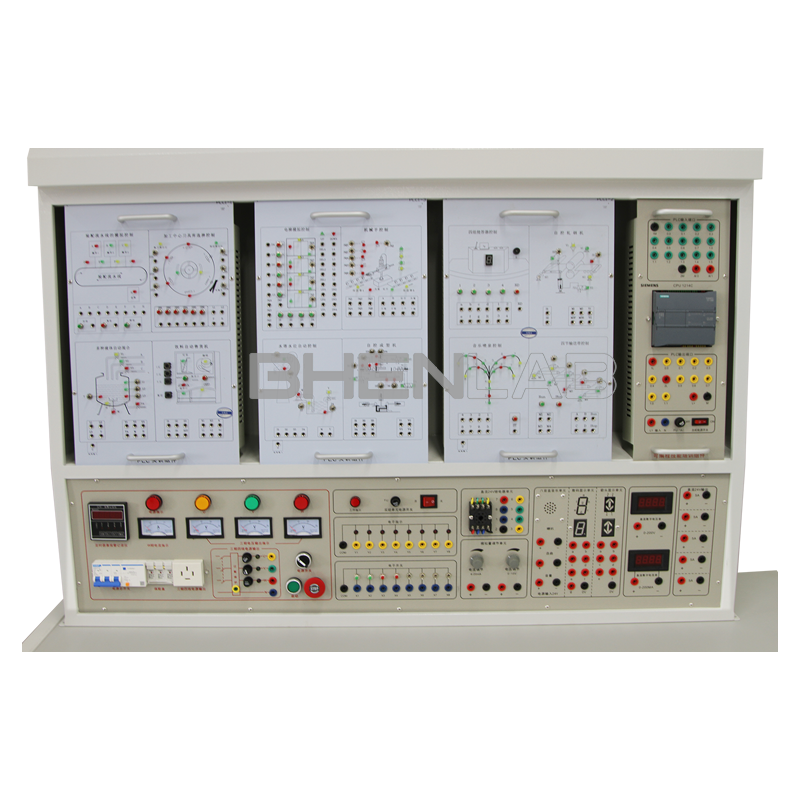

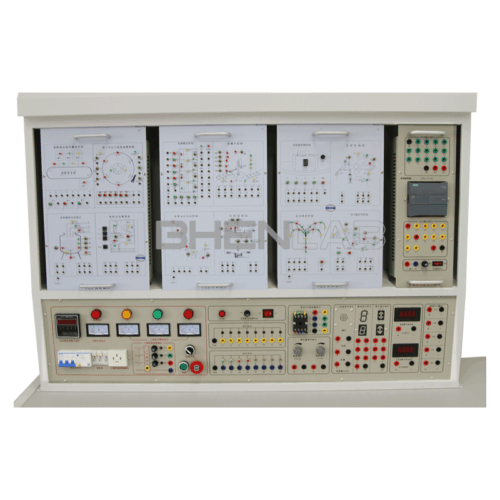

PLC Programmable Controller Demonstration Device

This device is an external demonstration device designed to be used with the PLC programmable controller experiment bench. It uses executive mechanisms such as LED light-emitting diodes, large LED nixie tubes, DC motors, stepping motors and other peripheral circuits to simulate the state in the actual industrial control process. It vividly demonstrates the entire execution process of PLC. Through this device, students’ hands-on ability can be trained, they can vividly verify the correctness of the programs they write through the executive mechanisms, master the practical application of PLC, and enhance students’ interest in learning PLC. The position of the device on the demonstration screen can be moved and swapped arbitrarily.

The input and output of PLC on the demonstration device both use 24V power supply, and 5V power supply is used for the peripherals in the executive mechanisms. At present, each set of demonstration device is mainly composed of 16 demonstration boards, whose models are as follows:

- PLC automatic control of traffic lights

- PLC automatic control of water tower water level

- PLC automatic control of automatic forming machine

- PLC automatic control of automatic rolling mill

- PLC automatic control of multiple liquid automatic mixing

- PLC automatic control of automatic feeding and loading system

- PLC automatic control of mail sorting machine

- PLC automatic control of elevator

- PLC automatic control of manipulator

- PLC simulation control of five-phase stepping motor

- PLC automatic control of automatic beverage vending machine

- PLC automatic control of automatic washing machine system

- PLC automatic control of electroplating workshop production system

- PLC automatic control of machining center tool magazine selection

- LED nixie tube experiment

- PLC automatic control of Tianjin Tower lights

Advantages: The connection between the PLC experiment bench and the demonstration device can use self-locking connectors for single-line point-by-point connection to improve hands-on and thinking abilities and deepen the understanding of the structure and function of PLC. It can also be connected at one time through a flat cable to improve the speed of experiments. Compared with the single connection method of other manufacturers, it has absolute advantages.

| Serial Number | Equipment Name | Specification and Model | Unit | Quantity |

| 1 | Experiment screen | Spray-painted steel structure | Set | 1 |

| 2 | Experiment desk | Steel structure | Piece | 1 |

| 2 | PLC host | Mitsubishi FX3U-48MR | Set | 1 |

| 3 | Experiment desk | All-steel structure, tabletop with post-formed fireproof board | Piece | 1 |

| 5 | Experiment stool | ABS stool surface, steel structure | Piece | 2 |

| 6 | Teacher’s chair | Five-wheel swivel chair | Piece | 1 |

| 7 | Programming cable | Mitsubishi special programming cable | Set | 1 |

| 8 | Three-phase power supply | High-reliability safety pistol socket | Group | 1 |

| 9 | DC regulated power supply | Adjustable 0~30V DC voltage | Group | 1 |

| 10 | Pulse signal source | Can provide “single” or “continuous” pulse signals with adjustable frequency | Group | 1 |

| 11 | Protection circuit | Short-circuit and leakage protector | Piece | 1 |

| 12 | Experimental connecting wire | One-time forming elastic pistol plug wire | Set | 1 |

| 13 | Experimental program (CD) | (Mitsubishi programming software / Mitsubishi PLC experimental program / Mitsubishi simulation configuration experimental program) | Set | 1 |

| 14 | Experimental instruction book | Set | 1 | |

| 15 | User manual | Set | 1 | |

| 16 | Experimental module | PLC001 Traffic light PLC automatic control | Block | 1 |

| PLC002 Stirrer PLC automatic control | Block | 1 | ||

| PLC003 LED nixie tube display PLC automatic control | Block | 1 | ||

| PLC004 Four-story elevator PLC automatic control | Block | 1 | ||

| PLC005 Machining center tool magazine selection control | Block | 1 | ||

| PLC006 Artistic color light modeling PLC control | Block | 1 | ||

| PLC007 Motor automatic control | Block | 1 | ||

| PLC009 Simulated TV transmitting tower | Block | 1 | ||

| PLC010 Automatic feeding and loading system | Block | 1 | ||

| PLC011 Automatic vending machine | Block | 1 | ||

| PLC012 Automatic forming system | Block | 1 | ||

| PLC013 Water tower automatic water supply system | Block | 1 | ||

| PLC014 Mail automatic sorting system | Block | 1 | ||

| PLC015 Automatic washing machine system | Block | 1 | ||

| PLC016 Electroplating system | Block | 1 | ||

| PLC008 Stepping motor PLC control | Block | 1 |